You might have heared about the progress made on the colossal Fehmarnbelt under-sea tunnel, connecting Denmark and Germany.

This massive undertaking, valued at €7.1 billion (US$7.5 billion), is currently in full swing. Concrete sections essential for constructing the immersed tube tunnel are now being manufactured at an expansive factory near the Danish entry point in Rødbyhavn.

Once finished, this tunnel will not only facilitate road traffic but also accommodate rail transportation. The Fehmarnbelt project is poised to become the world’s longest immersed tube tunnel upon completion, presenting a groundbreaking engineering achievement. However, it’s important to note that it doesn’t currently hold the title for the longest road tunnel under construction, though it does secure a spot among the top five remarkable projects worldwide.

This development is a testament to the remarkable progress in infrastructure projects, showcasing the dedication and ingenuity required to create such monumental structures.

The construction of this tunnel involves intricate planning, cutting-edge technology, and the collaborative efforts of skilled professionals.

As this project unfolds, it not only connects two nations but also serves as a symbol of human innovation and the ability to overcome complex challenges in the realm of civil engineering.

Here are the five longest road tunnels currently under construction around the world:

Daliangshan No.1 Tunnel, China

China Railway 18th Bureau is actively engaged in constructing the Daliangshan No.1 Tunnel, a critical component of the extensive 152km-long Sichuan Lexi Expressway situated in southwest China.

This expressway tunnel, stretching over a remarkable 15.3km, traverses the challenging terrain of the Liangshan mountains, making it reputedly the longest in the region. What sets this project apart is the use of innovative technology—a Tunnel Boring Machine (TBM)—instead of traditional blasting and drilling methods.

Like Us on Facebook!

The geological composition around the tunnel primarily consists of sandstone and silty mudstone. Negotiating these conditions is the formidable TBM, known as ‘Yuecheng Liangshan,’ with a diameter of 7.9 meters. The construction team faces intricate challenges, including faults in the rock and areas prone to water inrush, demonstrating their adeptness in navigating difficult geological conditions.

Subscribe Us on YouTube!

The entire expressway project, inclusive of the Daliangshan No.1 Tunnel, is anticipated to reach completion by July 2025. This endeavor signifies not only a feat in engineering and construction but also showcases the application of cutting-edge technology to overcome geological complexities, ensuring safer and more efficient tunnel construction in the Liangshan mountains.

- Longest in Region: Stretches an impressive 15.3km through the Liangshan mountains in southwest China.

- Innovative Technology: Utilizes Tunnel Boring Machine (TBM) instead of traditional blasting and drilling.

- Geological Challenges: Navigates sandstone and silty mudstone with a 7.9m-diameter TBM.

- Completion Deadline: Entire expressway project, including the tunnel, set to complete by July 2025.

- Technological Application: Demonstrates cutting-edge technology for safer tunnel construction in challenging terrains.

Förbifart Stockholm

Förbifart Stockholm is an extensive project involving the construction of a network of underground tunnels designed to create a bypass around the capital city of Sweden, Stockholm.

This ambitious initiative covers a substantial distance, with 18km of the upcoming 21km extension of the E4 motorway dedicated to these underground passageways. The purpose of this development is to enhance the connectivity between the northern and southern regions of Stockholm.

Initiated in 2016, this intricate project is expected to conclude by 2031, involving a significant investment of SEK 41.7 billion (equivalent to US$3.8 billion). The construction process has been meticulous, with contractors successfully completing nearly 10km of rock tunnels. These tunnels, reaching depths of up to 70m, have been created using the drill and blast method. This method was chosen due to the prevailing geological conditions characterized by gneiss and granite rock in the area. The stability of these tunnels is ensured through the implementation of rock bolts and shotcrete.

Following the excavation process, the next steps involve shoring work and the erection of prefabricated tunnel walls. Additionally, contractors are tasked with the installation of essential infrastructure elements. This includes laying pipes for cables and water, establishing sewage systems, and casting foundations for road signs and traffic monitoring cameras.

The construction of this bypass is divided into six distinct lots. Among these, Implenia secured a contract to build the 3.6km long Johannelund tunnel, with an anticipated completion date in 2024. In 2020, AF Gruppen was assigned to construct 6km of the E4 Förbifart Stockholm, encompassing a 6km twin-tube tunnel and 7km of ramp tunnels. Other notable contractors involved in this expansive scheme include Skanska, Veidekke Construction, and NCC, each contributing to different facets of this transformative infrastructure endeavor.

- Extensive Bypass Project: Covers 18km of the new 21km E4 motorway extension around Stockholm.

- Meticulous Construction: Involves nearly 10km of rock tunnels using drill and blast method.

- Strategic Division: Construction divided into six lots, each addressing different aspects of the bypass.

- Infrastructure Enhancement: Includes laying cables, water pipes, sewage systems, and foundations for road signs.

- Scheduled Completion: Overall project expected to conclude by 2031, enhancing connectivity in Stockholm.

Fehmarnbelt

Denmark’s impressive Fehmarnbelt, spanning 18 kilometers and connecting Denmark to Germany, is poised to claim the title of the world’s longest immersed tube tunnel (IMT) upon the completion of its €7.1 billion (US$7.5 billion) project.

What sets this tunnel apart is its dual functionality as the world’s longest combined road and rail tunnel. The decision to employ an IMT was driven by economic feasibility, offering a less risky alternative to a bored tunnel, particularly in an area known for robust prevailing east-west winds.

The Fehmarnbelt tunnel is a significant engineering feat, nearly three times longer than the IMT section of the Hong Kong-Zuhai-Macau Fixed Link, currently holding the record as the world’s longest tube tunnel.

The execution of this monumental project involves several key players. Femern A/S, overseeing the project, dedicated two years to constructing a specialized harbor capable of handling up to 80,000 tonnes of material weekly. Additionally, the world’s largest tunnel factory is actively creating tunnel sections at the Danish entrance in Rødbyhavn.

The Fehmarn Belt Contractors (FBC), a collaborative effort between Boskalis and Van Oord, has been at the forefront of crucial dredging and marine work. Simultaneously, the Fehmarn Link Contractors (FLC) consortium, consisting of Vinci, BAM, Per Aarsleff, Wayss & Freytag Ingenieurbau, and Max Bögl Stiftung, has been instrumental in constructing the tunnel, portal buildings, casting factory, and workers’ accommodations since January 2021.

Ensuring the tunnel’s functionality, Femern Systems Contractors (FSC) will equip it with essential lighting and safety systems. Meanwhile, Elecnor is actively engaged in constructing a substantial transformer station in Rødbyhavn to supply power to the tunnel’s railway.

Anticipated to open in mid-2029, the Fehmarnbelt tunnel stands as a testament to collaborative engineering excellence and technological innovation, connecting nations and enabling efficient transportation between Denmark and Germany.

- World’s Longest IMT: Spanning 18km, set to be the world’s longest immersed tube tunnel.

- Combined Road and Rail: Uniquely serves as both a road and rail tunnel for enhanced connectivity.

- Economic Viability: Opted for an Immersed Tube Tunnel (IMT) due to economic feasibility.

- Major Collaborations: Involves various entities like Femern A/S, Fehmarn Belt Contractors (FBC), and Fehmarn Link Contractors (FLC).

- Opening Projection: Anticipated to open in mid-2029, symbolizing collaborative engineering excellence.

Tianshan Shengli Daban Tunnel, China

The construction of the impressive Tianshan Shengli Tunnel, undertaken by China Communications Construction Company (CCCC), is making significant strides. This tunnel, spanning 22.1 kilometers, is currently the lengthiest highway tunnel under development in China.

Nestled beneath the remote Tianshan Mountains in the elevated reaches of 3,200 meters, this tunnel is a crucial component of a vast 1,300-kilometer expressway that links Xinjiang’s capital, Urumqi, to Yuli County in China’s northwest Xinjiang Uygur Autonomous Region.

Commencing in 2020, this extensive six-year project is organized into three distinct sections, interspersed with four shafts strategically placed along its course. The tunnel boring machines powering this endeavor are crafted by the adept hands of the Chinese manufacturer Zhongjiao Tianhe.

This ambitious project not only serves as a testament to engineering prowess but also plays a pivotal role in enhancing regional connectivity. By establishing an efficient route through the challenging terrain of the Tianshan Mountains, it is set to contribute significantly to the transportation network between Urumqi and Yuli County, fostering economic and social development in the Xinjiang Uygur Autonomous Region.

- Lengthiest Highway Tunnel: Spans 22.1km under the Tianshan Mountains in Xinjiang, China.

- Strategic Expressway Link: Part of a 1,300km expressway connecting Urumqi to Yuli County.

- Tunnel Boring Machines: Divided into three sections, utilizing tunnel boring machines by Zhongjiao Tianhe.

- Regional Connectivity: Enhances connectivity through challenging Tianshan Mountain terrain.

- Project Commencement: Started in 2020, a six-year project contributing to regional economic development.

Rogfast Tunnel, Norway

The Rogfast Tunnel, also known as the Boknafjord Tunnel, located in Norway, is poised to claim the title of the world’s longest and deepest subsea road tunnel. It’s a colossal engineering marvel, reaching a maximum depth of 392 meters below sea level and spanning an impressive total length of 26.7 kilometers.

This extraordinary tunnel serves as a vital link between the municipalities of Randaberg near Stavanger and Bokn in Rogaland, facilitating the flow of traffic on the E39 highway.

Construction endeavors commenced in 2018, but unfortunately, faced a setback in October 2019 due to unforeseen cost overruns. Despite these challenges, the Norwegian Public Roads Administration demonstrated resilience by dividing the project into three substantial tunneling contracts.

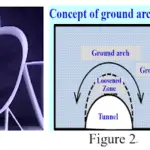

These contracts encompass various segments, including the extensive southern tunnel segment from Bokn, the Kvitsøy tunnel segment, and the extensive northern tunnel segment from Randaberg. Each of these segments presents unique challenges, including intricate tunnel interfaces, formidable geological conditions, high water pressure, intricate leakage prevention measures, and the implementation of longitudinal ventilation systems.

The intricate construction involves collaborations with esteemed contractors. Skanska secured a substantial deal worth NOK 5 billion (US$460 million) for the construction of the northern part of the tunnel, featuring a twin segment with 18.5 kilometers of road within the tunnel and an additional 2 kilometers above ground. Simultaneously, a collaborative effort between Implenia and Stangeland Maskin successfully clinched the E03 segment, consisting of an 8.6km-long, two-tube tunnel stretching from Harestad northwards to a midpoint between Tungenes and Kvitsøy. The contract value for this joint venture is estimated at NOK 4 billion (US$370 million).

While Skanska is anticipated to complete its segment by 2029, the Implenia-Stangeland Maskin joint venture is set to conclude their portion of the project in 2030. Despite the challenges faced, the Rogfast Tunnel stands as a testament to perseverance and innovative engineering, significantly contributing to Norway’s transportation infrastructure.

- World’s Longest Subsea Tunnel: A colossal 26.7km tunnel beneath Boknafjord, reaching 392m below sea level.

- Segmented Contracts: Divided into three contracts for southern, northern, and Kvitsøy tunnel segments.

- Challenging Conditions: Faces intricate tunnel interfaces, geological challenges, and high water pressure.

- Contractor Collaborations: Involves collaborations with Skanska, Implenia, and Stangeland Maskin.

- Completion Projections: Skanska expected to finish by 2029, showcasing perseverance in overcoming challenges.