California Bearing Ratio (CBR) test is a compressive nature penetration test. It was originally developed by Caltrans i.e. California Department of Transportation after World War II i.e. in the late 1930s.

The test is specifically used to determine the mechanical strength as well as the potential strength of road subgrades and basecourses materials including the recycled material generally used for road and airfield pavements. CBR value is a percentage comparison with the standard crushed rock from California and thus this test is a comparison test.

The test is standardized by American Society Of Testing Materials (ASTM) as D1883-05 (this standard is used for laboratory prepared samples or re-molded samples) and D4429 (for on field soils); and by American Association of State Highway and Transportation officials (AASHTO) T193; and by British Standard as BS 1377; and by International Standard (IS) as 2720 (Part XVI).

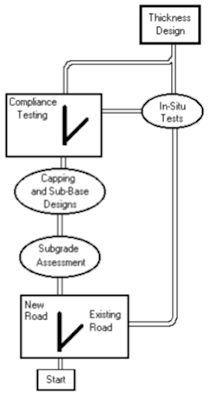

Main components of Pavement design

The results obtained by CBR test are used with the empirical curves to determine the thickness of different layers of flexible pavement like subgrade, subbase, base courses. This is the most widely used method for the design of flexible pavement.

CBR value is used to quantify the response of the pavement foundation and subgrade to loading. CBR does not provide any data regarding the properties of the soil except as to compare its resistance to penetration to the base crushed rock’s resistance to penetration. Although CBR test is empirical and has some limitations but it is still used around the world due to its low equipment requirement, ease of performance prediction and history of use.

The two empirical methods for pavement design used now days are CBR method and Group Index Method. In CBR method beside many other steps one step is to determined the CBR value. This test allows the Engineer to design the Capping Layer and the sub-base layer by determining the strength of the underlying soil.

|

|

| Flowchart for pavement design using CBR method |

Scope and Objective of the CBR Test

The Objective of the California Bearing Ratio test is to determine the CBR value for a soil under consideration as a pavement foundation.

CBR is generally used for cohesive soils where effect of water content on CBR is more and generally CBR is determined for a range of water content but it can also be performed for cohesionless soils or coarse grained materials where the effect of water content on CBR is small and thus CBR is performed at Optimum Moisture Content (OMC).

According to ASTM; CBR is primarily intended for evaluating the strength of materials having maximum particle sizes less than ¾ inches or 19 mm, but this restriction is not strict one; if the sample has a material larger than 19 mm; equal amount of such material be replaced by material of size smaller than 19 mm but from the same representative sample.

If the sample to be tested contains much fraction of particles of sizes 3 in (Sieve No. 4), the CBR results will fluctuate and thus more trials are required to establish a reliable CBR; thus generally the sample to be tested consists of particles smaller than 19 mm but larger than 3 in.

CBR test can be performed for both in soaked conditions or un-soaked conditions; but mostly soaked conditions is preferred so as to evaluate the material strength in worst conditions.

Description of Apparatus

Apparatus required to perform the CBR test is as follows;

- Molds: Cylindrical mold with an internal diameter of 6 in. and a height of 7 in. with an extension collar of 2 in. height and a perforated base plate.

- Spacer Disk: A circular disk of metal 5 – 15/16 in. diameter and 2.416 in. height.

- Rammer: A rammer of mass 4.54 kg (10 lbs)

- Apparatus for measuring expansions. This consists of a swell plate with adjustable stem and a tripod support for a dial indicator.

- Surcharge weights: Several slotted or split metal plates of 149.2 mm; diameter and 5 lb weight.

- Penetration Piston: A metal Piston of circular cross – section having diameter of 1.954 in. Area = 3in2 and not less than 4 inches in length.

- Loading Device: A compression type apparatus capable of applying a uniformly increasing load up to 10,000 lb at a rate of 1.3 mm/min.Soaking Tank: A tank suitable for maintaining the water level of 1 in, above the top of specimen.

- Drying Oven: Oven Capable of maintaining a temperature of 110 + 5 0C for drying samples.

- Moisture content Containers

- Miscellaneous: Tools such as mixing pans, spoons, straightedge, filter paper, balances etc.

Test procedure

- Approximately 18 kg soil pass of 19mm sieve and retain of sieve no. 4 is taken.

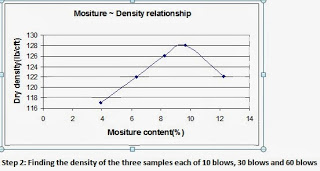

- Moisture and dry density curve is obtained using the standard AASHTO T 99 or T 180.

- Optimum Moisture Content (OPC) is obtained from the graph between moisture content and dry density

- Prepare the sample by adding optimum moisture content and then compact the soil in five layers by applying 10,30 and 65 blows respectively in three CBR molds using 10 lb rammer having 18 in. height of fall. The compacted densities of the three specimens range from 95 percent to 100 % of the maximum dry density already determined by the T 180 compaction test.

- Soaking: Place the swell plate with adjustable stem on the soil sample in the mold and apply sufficient annular weights to produce an intensity of loading equal to the mass of sub-base and base courses and surfacing above the tested material, but not less than 4.54 kg (10 lbs) . Place the tripod with dial indicator on top of the mold and make an initial dial reading.

- Immerse the mold in water to allow free access of water. Place the sample in water for 96 hours (4 days)

- Make a dial reading on soaked specimen and calculate swell as a percentage of initial sample height.

- Remove the sample from tank and allow to drain for 15 minutes.

- Penetration Test: Place the mold on the loading frame and adjust its potion until the piston is centered on the specimen.

- Seat the penetration piston with a 44 N (10 lb) load, and set both the load dial and the strain dial to zero. This initial load is considered as the zero load when determining the stress-penetration relationship.

- Place the surcharge weights on the specimens equal to that used during soaking. Apply load at a rate of 1.3 mm / min and record the load for penetration of 0.025 in, 0.05 in, 0.075 in, 0.10 in and so on up to 0.5 inches.

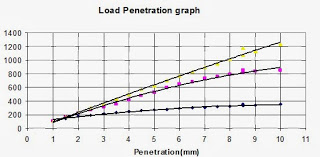

- Stress strain curve: Plot curves between load and penetration for each specimen. Apply the corrections to the curves if required. Take the readings of load for 0.1 in and 0.2 in. penetration and find CBR for both penetrations. The greater values is the required CBR for that specimen. Also find the dry density for each specimen.

- CBR = Test load value, divided by, the standard load, multiplied by 100.

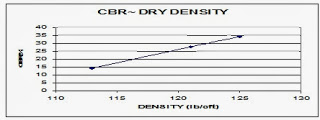

- Design CBR: it is calculated by plotting a graph between CBR values and dry densities of all the three specimens and then calculating the design CBR against value of 85 % maximum dry density.

Test results, table ,graphs and calculations

Step 1: Getting the relationship and graph between moisture content and dry density

|

| Moisture Density Relationship |

Dry Density (lb/cft)

|

Sample No.

|

Moisture Content (%)

|

Dry Density (lb/cft)

|

|

1

|

||

|

2

|

||

|

3

|

||

|

4

|

||

|

5

|

Step 2: Finding the density of the three samples each of 10 blows, 30 blows and 60 blows

Step 3: Load v/s Penetration Graph

|

| Load Penetration Curve |

For sample made with 10 blows

|

Sr.No

|

Load (lbs)

|

Penetration (mm)

|

|

1

|

0.5 mm

|

|

|

2

|

1.0 mm

|

|

|

3

|

1.5 mm

|

|

|

4

|

2.0 mm

|

|

|

5

|

2.5 mm

|

|

|

6

|

3.0 mm

|

|

|

7

|

3.5 mm

|

|

|

8

|

4.0 mm

|

|

|

9

|

4.5 mm

|

|

|

10

|

5.0 mm

|

|

|

11

|

5.5 mm

|

|

|

12

|

6.0 mm

|

|

|

13

|

6.5 mm

|

|

|

14

|

7.0 mm

|

|

|

15

|

7.5 mm

|

|

|

16

|

8.0 mm

|

|

|

17

|

8.5 mm

|

|

|

18

|

9.0 mm

|

|

|

19

|

9.5 mm

|

|

|

20

|

10 mm

|

For sample made with 30 blows

|

Sr.No

|

Load (lbs)

|

Penetration (mm)

|

|

1

|

0.5 mm

|

|

|

2

|

1.0 mm

|

|

|

3

|

1.5 mm

|

|

|

4

|

2.0 mm

|

|

|

5

|

2.5 mm

|

|

|

6

|

3.0 mm

|

|

|

7

|

3.5 mm

|

|

|

8

|

4.0 mm

|

|

|

9

|

4.5 mm

|

|

|

10

|

5.0 mm

|

|

|

11

|

5.5 mm

|

|

|

12

|

6.0 mm

|

|

|

13

|

6.5 mm

|

|

|

14

|

7.0 mm

|

|

|

15

|

7.5 mm

|

|

|

16

|

8.0 mm

|

|

|

17

|

8.5 mm

|

|

|

18

|

9.0 mm

|

|

|

19

|

9.5 mm

|

|

|

20

|

10 mm

|

For sample made with 60 blows

|

Sr.No

|

Load (lbs)

|

Penetration (mm)

|

|

1

|

0.5 mm

|

|

|

2

|

1.0 mm

|

|

|

3

|

1.5 mm

|

|

|

4

|

2.0 mm

|

|

|

5

|

2.5 mm

|

|

|

6

|

3.0 mm

|

|

|

7

|

3.5 mm

|

|

|

8

|

4.0 mm

|

|

|

9

|

4.5 mm

|

|

|

10

|

5.0 mm

|

|

|

11

|

5.5 mm

|

|

|

12

|

6.0 mm

|

|

|

13

|

6.5 mm

|

|

|

14

|

7.0 mm

|

|

|

15

|

7.5 mm

|

|

|

16

|

8.0 mm

|

|

|

17

|

8.5 mm

|

|

|

18

|

9.0 mm

|

|

|

19

|

9.5 mm

|

|

|

20

|

10 mm

|

Summary of CBR Test and conclusion

|

Sample No.

|

Compaction Effort

|

Dry Density (lb/cft)

|

CBR value (%)

|

|

1.

|

10

|

113

|

14.5

|

|

2.

|

30

|

121

|

28

|

|

3.

|

65

|

125

|

34.5

|

Maximum Dry density _____________________ (lb./cft)

95% of maximum dry density________________(lb/cft)

Resultant CBR or Designed CBR __________________ (lb/cft)

|

| CBR – Density Relation |

Limitations

The laboratory and field compaction methods are not identical, however, comparative tests indicate that reasonable correlation of results can be obtained from field compact materials and samples compacted under similar conditions in the laboratory.

Because added strength to highly stabilized surfaces such as asphaltic concrete is neglected, the assumption of a completely saturated subgrade condition sometimes results in a too conservative factor of safety.

Because many of the procedures are of an arbitrary nature, you must run the test to exact standards in order for the design tables to be valid.

Conclusion:

California bearing ratio is a widely used method to design the flexible pavements, beside all the limitations it is easy to perform and still does not need any big instruments etc. The value of the CBR test is then compared with the following table to get the quality of material from which the required thicknesses and other parameters are decided.

|

CBR VALUE

|

SUBGRADE STRENGTH

|

COMMENTS

|

|

3% and less

|

Poor

|

\” Capping is required

|

|

3% – 5%

|

Normal

|

Widely encountered CBR range capping considered according to road category

|

|

5% – 15%

|

Good

|

\”Capping\” normally unnecessary except on very heavily trafficked roads.

|

I am using Novo Formula and highly recommend it

I am using Novo Formula and highly recommend it