GSB is an acronym for Granular Sub Base. As the name suggests, it is a granular material that act as road foundation and takes up as sub-base layer above the compacted sub-grade surface. The basic purpose of granular sub-base is to protect the base and wearing course from the capillary water action from the subgrade. The gradation of the GSB is decided so the layer can stop the water from seeping to the higher layers. It acts like a drainage layer that is very critical in the longevity and durability of road pavement.

Composition of GSB

Granular sub-base material typically comprised of crushed stone aggregate. It must be ensured that no organic material or deleterious constituents are present. You can also use natural river bed material but make sure to have proper gradation.

According to The Ministry of Road Transport and Highways; the gradation must be grade-1 with percentage passing 0.075mm restricted to 5%. Alongside, the material needs to be tested on CBR after soaking for four days. The CBR minimum allowed is 30%.

Characteristics of GSB materials

- Granular sub-base (GSB) is an essential component in road construction, as it provides a stable base for the road surface.

- The GSB layer is composed of a mix of crushed aggregates from approved sources, which are proportioned to achieve the specified grading. The composition of GSB must meet specific requirements to ensure its strength and stability.

- According to IS 2720 (Part-37), the portion of the total aggregate passing through a 4.75mm sieve must have a sand equivalent value of not less than fifty.

- The proportioning of the GSB materials is done by determining the proper gradation of the individual ingredients and the blend, which is determined by trial and error method to achieve the gradation specified.

- Maximum dry density and Optimum Moisture content must be well established beforehand. This will ensure that the material has a CBR value of 30% or more upon compaction and finishing.

- During the construction process, if there is a variation in the gradation, the proportion shall be suitably modified, and the entire required tests shall be carried out per relevant specification.

- The material must be blended at source/crusher to achieve the specified gradation and shall be jointly checked at the site for conformance to gradation and other tests as defined in section 900 of MORTH.

Construction procedure for GSB layer

Marking the GSB Layer

Before the construction of GSB, it is essential to mark the outside lines of the GSB layer with lime powder or pegs on the completed subgrade. This helps to ensure that the GSB layer is constructed within the designated area.

Drainage System

It is important to ensure that the requisite sub-surface drain and drain outlet at the level of sub-grade/sub-base are completed before GSB construction. This is to ensure that proper drainage is in place to prevent water from pooling on the road surface.

Preparing the Subgrade

Before the sub-base is laid, the existing subgrade will be finished by removing all vegetation and other sub-extraneous matter. The subgrade should be lightly sprinkled with water if necessary and rolled with two passes of 80 -100 KN smooth wheeled roller.

Loading and Transporting the GSB Material

The GSB material is loaded with the help of a loader on dumpers and transported to the GSB location. The required material should be dumped between the limiting lines previously marked with the help of lime powder.

Spreading and Compacting GSB Material

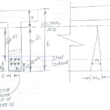

The material of the GSB layer confirming Table 400.1 shall be spread in layers of uniform thickness of 200 mm compacted thickness for new flexible pavement and 150 mm compacted thickness for Service Roads and rigid pavement.

A grader shall be used for this activity. The moisture content of the material should have OMC +1.0% or –2.0%. If not, either a mixing or drying process must be adopted. Water can be added to raise the moisture content to the required limits.

Like Us on Facebook!

After spraying water with the browser, the material shall be properly mixed to obtain a homogeneous mix. The mixing can continue with the help of a grader. The grader shall then carry out the final well-defined grading.

Subscribe Us on YouTube!

For more information about granular sub-base and its importance in road construction, you can refer to the following websites:

- Indian Road Congress (IRC) – http://irc.gov.in/

- Ministry of Road Transport and Highways (MORTH) – https://morth.nic.in/

- Indian Standards Institution (ISI) – https://www.isibang.ac.in/

- Central Road Research Institute (CRRI) – https://www.crridom.gov.in/

- Indian Geotechnical Society – http://www.igs-india.com/