From everyday household tasks to constructing towering skyscrapers, fasteners play a crucial role in our lives. Fasteners and their different types plays a vital role in various projects relating to engineering, contractor or DIY. Given below are details of fasteners and their types that will be utilized in different fields. Let’s explore them!

Fasteners

It is defined as mechanical device, that are used to connect one or more surfaces, which may be temporary or permanent depending upon the nature of material that utilizes it. Temporary fasteners like screws, nuts & bolts and washers are easily removed without causing any detrimental effect on the joined materials. On the other hand, permanent fasteners are used to create strong bond, making it difficult to disconnect them.

Examples of permanent fasteners include weld nuts and rivets.

Different Types of Fasteners

As the name indicated that, these are materials that are used for connecting the two similar or different materials, used in vide variety of projects.

Threaded fasteners are the most prevalent type, featuring internal threads that fit into corresponding threaded holes in other pieces.

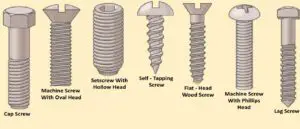

Numerous types includes; wood , sheet metal, self-tapping and machine screws.

These fasteners may have hexagonal or rounded heads and smooth shanks.

Here are some of the more common types of fasteners:

Screws

Screws play a crucial role as essential fasteners in a wide range of applications, whether it’s joining wooden boards or securing electrical components. They come in various forms, including coarse threads to fine deck screws, each designed for specific purposes, whether for indoor or outdoor use.

Like Us on Facebook!

- Wood screws: it is the most commonly used type, are ideal for joining wood, thanks to their tapered head that allows them to sink easily into the material. On the other hand, sheet metal screws also feature a tapered thread, but they are specifically designed for attaching metal to other materials like wood or plastic.

- Machine screws, : it is thicker than wood and sheet metal screws, are well-suited for holding different parts of machinery or appliances together. In most cases, machine screws require the use of nuts and bolts to complete the fastening job.

2. Socket Screw

Socket screws, distinguished by their Allen head and sometimes smooth shanks, belong to the category of threaded fasteners and are fastened using an Allen key.

Subscribe Us on YouTube!

These screws are available in different head shapes, such as button heads, socket heads, and flat heads, and they are highly effective for permanently joining metal sheets, wood, and various other materials.

Compared to self-tapping screws and other mechanical fasteners, socket screws offer exceptional strength and deliver high-quality results.

For enhanced stability and performance, socket screws can be combined with hexagonal nuts, flat washers, pipe plugs, or other types of washers.

Due to their versatility, durability, and ease of single-use application, socket screws are popular choices among common hardware fasteners. They come in various sizes and variations, making them easy to install into threaded holes.

Some of the available types of socket screws include socket heads, button heads, flat heads, locking screws, shoulder bolts, and many more.

When installed correctly using quality materials, socket screws provide reliable long-term holding power for multiple applications that demand robust and secure fastening.

3. Machine Screws

Machine screws are a fundamental component used in various machinery and are widely adopted as common fasteners. These threaded fasteners feature a cylindrical head with internal threads and can be compared to sheet metal screws.

These are very easy to install without making the need to create the bore hole, can be installed at an ease in to the pre-drilled holes. Due to its variety of sizes, length and diameters available in market, making it a indispensable product.

Regardless of the specific type chosen, machine screws deliver a secure and reliable connection between two pieces of metal or other materials. Their reliable performance makes them an integral part of countless projects and machinery applications.

It different types are listed below:

Tipping Screws

Tapping screws are specially designed fasteners featuring a threaded shank and, in some cases, a pointed tip. This unique design allows them to be directly tapped into pre-drilled holes, making them highly suitable for use in metal sheets or materials where creating a hole during installation is not feasible.

Due to variety of different shapes, sizes and lengths, extending from flat to round head, you can easily find the perfect tapping screw for the intended purposed of your project. Different types include thread cutting, self-tapping, self-drilling etc

Regardless of the specific type chosen, tapping screws serve as essential hardware tools, offering unparalleled strength and durability for diverse applications.

Nuts and Bolts

Nuts & bolts are widely used as fasteners to join separate pieces together. The bolt is inserted through the parts and secured with a nut on the opposite end.

Carriage bolts have a domed or countersunk head with a square section beneath it, ensuring the bolt stays in place. Flange bolts, on the other hand, have an additional circular flange beneath the head to evenly distribute loads.

These bolts come with hexagonal heads, rounded heads, or even as self-tapping screws for various applications, including sheet metal. To enhance stability between components, fasteners like these are often used to join metal to wood, along with flat washers or other washer types.

Here is the detail of different types of Nut & bolt:

Hex Nuts

These are six-sided in shape, ideally worked well for metal and wood projects and can be easily assembled with a wrench. They are made up of high quality steel

They remain popular due to their usage, veracity in different shapes and sizes and utilized in variety of applications.

Available in various sizes, they provide reliable connections for a multitude of project needs.

3. Washers

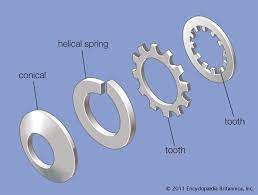

Washers are essential fasteners utilized across various industries. Their primary function is to be placed under joints, nuts, and axle bearings to minimize friction and prevent components from loosening due to vibrations.

Furthermore, washers serve to isolate different components and prevent potential leakage. While the shapes of washers vary depending on their specific purposes, their fundamental goal remains the same: securing two surfaces together with a single fastener.

Washers are available in various materials like metal, plastic, rubber, or fiberglass. The selection of materials depends on the application, considering factors such as moisture-resistance properties or corrosion-resistance capabilities.

Among the common types of washers are flat washers. These fasteners are crucial for evenly distributing the load of bolts, screws, or nuts. They are widely used in numerous hardware applications, including metal to wood attachments.

Flat washers are compatible with various types of screws, such as machine screws, self-tapping screws, and wood screws. Additionally, they work well with threaded fasteners like bolts, nuts, and threaded holes with either internal threads or rounded hexagonal head designs.

Using the correct size of flat washer for each application is essential, as it ensures the strength and stability of the joint.

Overall, flat washers remain highly popular as fasteners due to their versatility and reliability in securely attaching components.

4. Rivets

- Rivets are a type of permanent fastener extensively used across various industries and applications. Once installed, these fasteners create a permanent joint that cannot be removed or reused. They are commonly employed for fastening metal sheets and plates together.

- Rivets typically possess a cylindrical shape with a long mandrel or shank, and their heads can be either hexagonal or rounded.

- In comparison to other types of fasteners, rivets exhibit superior strength, making them a preferred option where reliability and permanence are essential.

- While self-tapping screws, machine screws, nuts, and washers are popular hardware fasteners for joining metal sheet components, rivets excel in high-strength applications due to their exceptional strength, surpassing single-use fasteners like self-tapping screws or bolts.

Nails

Nails play a fundamental role in various construction projects and come in diverse shapes and sizes, each serving specific purposes. Among them, framing nails stand out as one of the most commonly used nails, designed specifically for building walls, roofs, and sub-flooring.

For a more refined look in your projects, finishing nails are available in smaller sizes with flat heads that seamlessly blend in with the overall aesthetic. These nails are ideal for securing delicate or visible elements like door jambs and crown molding.

Box nails, with their steel shafts and diamond point tips, are widely used in construction and framing. They are easy to drive into studs, making them a popular choice in many applications.

The proper selection of nail type is vital to ensure a secure fit that can withstand the test of time, enhancing the overall finish and durability of any project, regardless of its nature.