How many times as a civil engineer, you have to test a concrete? Hunh! So many Times! But most of the time you find concrete cubes and cylinders being crushed by Compression Testing Machine (CTM) in the laboratory. Now that broken cylinder or cube is useless for you, although you can recycle it but even then a recycled material can never meet the standard of first class material. Think about hundreds of cubes and hundreds of cylinders being tested, broken and then the crew throw them away.

|

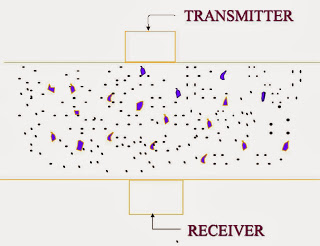

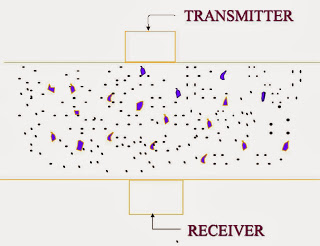

| Performing UPV test by direct method |

And then the Non-destructive Testing (NTD) comes to rescue;

“Non Destructive Testing are non invasive techniques to determine the integrity of a material, component or structure or quantitavely measure some characteristic of an object”

Non-destructive Testing is an easy way to detect or inspect the defects on the surface of the concrete or structure, It is a fast techniques and need not any sort of huge calculation or waiting, Mostly this technique is used in specialist high risk areas such as nuclear and Sea shore structures, gas and oil pipelines.

There are a lot of method involved in non-destructive testing like rebound test, ultrasonic pulse velocity test; Here we are focusing on Ultrasonic Pulse Velocity Test (UPV)

We know that velocity of ultrasonic waves is directly proportional to the density or in other words the modulus of elasticity of the material; and as far as the concrete is concerned we have a direct empirical relations between Modulus of Elasticity of Concrete (E) and compressive strength of the concrete (fc’). Thus if we can measure the velocity of ultrasonic waves through concrete we might easily get the compressive strength of the concrete.

|

| Idea of Receiver and Transmitter |

Methods of testing:

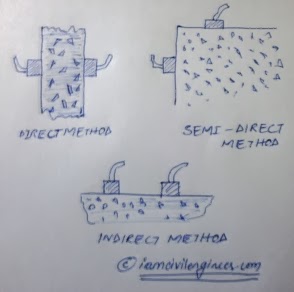

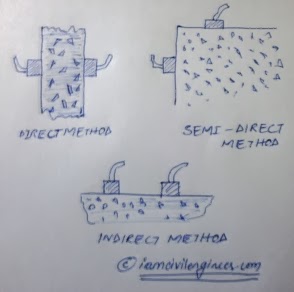

There are three methods of testing the concrete depending upon the placement of the transducers;

Direct Method:

If the two transducers are placed in such a way that one is placed at one end and other at the other end throughout the member it is direct method

Indirect method

In this method both transducers are place on the same surface of concrete and the receiver receives the pulse coming after striking the concrete molecules

Semi-direct method

It is mostly used for corners of concrete members

|

| Methods of UPV tests |

Apparatus Required:

Electrical Pulse Generator – Transducer – Amplifier Electronic Timing Device

Designation:

ASTM C597 – 09

How it is performed?

By using the calibration cylinder, first of all the calibration of the instrument was check, the default ultrasonic pulse velocity through the calibration cylinder was 57.8 micro seconds.

After calibration testing, on the two surface of the concrete some sort of vasline or any similar material is applied so that the two transducers might be leveled;

The travel time of velocity is read from instrument in microseconds; this travel time is converted to velocity by using the relation s=vt; or v=s/t; if we are testing two different ends of cylinder; the distance between transducer will be 1 feet thus velocity will be 1/t where t is converted to seconds from microseconds;

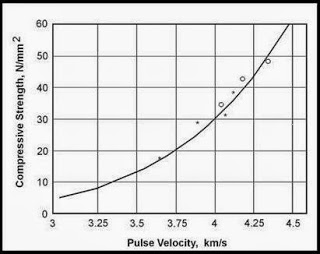

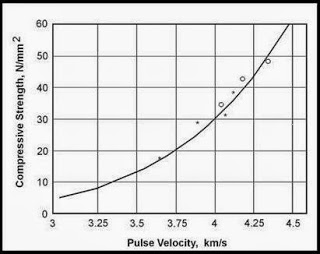

This velocity in ft/sec is then related to fc’ by using a graph between pulse velocity (ft/sec) on x-axis and fc’ (psi) on y-axis

|

| Graph Between Pulse Velocity and Fc\’ |

To compare the results between destructive compression testing of cylinder with this non-destructive compression testing; the cylinder is then tested with compression testing machine.

At the end the percentage difference between two fc’s is reported.

Discussion

The curves between fc’ and ft/sec velocity is different for dry concrete and we concrete; the reason being if the concrete is dry the voids will be filled with air; velocity of pulse through air being lesser then that in water the pulse velocity reading will be smaller in case of dry material then that of wet material.

The transducers must not touch the reinforcement bars in the concrete; as the assumption of this method is that the material must be homogeneous, isotropic and elastic;

Determining the Quality of Concrete Grading by using pulse velocity

Above 4.5 km/sec Excellent

3.5 to 4.5 km/sec Good

3.0 to 3.5 km/sec Medium

Below 3.0 Doubtful

|

| performing UPV test indirectly |

Advantages and Disadvantages of the Ultrasonic Pulse Velocity Test:

As far as the advantage of the ultrasonic pulse velocity is concerned; it has high penetrating power which ensure very easy measurement even for the very deep concrete members; it is highly sensitive thus giving accurate results; easy to use for estimating the size, shape and nature of flaws in the concrete member;

But this method also have some limitations like; manual operation of the instrument requires careful attention by experienced technicians; if the surface is irregular it is difficult to estimate accurately the pulse velocity; test objects must be water resistant.

This comment has been removed by a blog administrator.

This comment has been removed by a blog administrator.