Conservation of water supplies is increasingly important as the demand continues to increase and new sources of supply are becoming increasingly scarce.

The principle of conservation requires that full use of available water be made by minimizing the water loss due to seepage during conveyance in the canals.

Canal lining offers the solution because it helps conserve the costly impounded water otherwise lost during conveyance due to high seepage losses in unlined section.

Lining means protection of canal prism with impervious material. Canal lining may be rigid, semi rigid or flexible.

Objectives of Canal Lining

• To minimize the losses due to seepage

• To protect the area prone to water logging due to rise in water table

• To increase the discharge capacity of the canal

• Improvement of command and larger working head for power generation

Advantages of Canal Lining

• Reduction in seepage losses

Like Us on Facebook!

• Low maintenance cost

Subscribe Us on YouTube!

• Minimizes the possibility of breaching of canals

• Prevents weed growth

• Improved hydraulic efficiency of canals

• Reduces cross sectional dimensions of canal

• Improvement in command

Disadvantages of Canal Lining

• Higher initial investment

• Repair is costly

• Shifting of outlet is costly because it involve dismantling and relaying of lining.

• Longer construction period

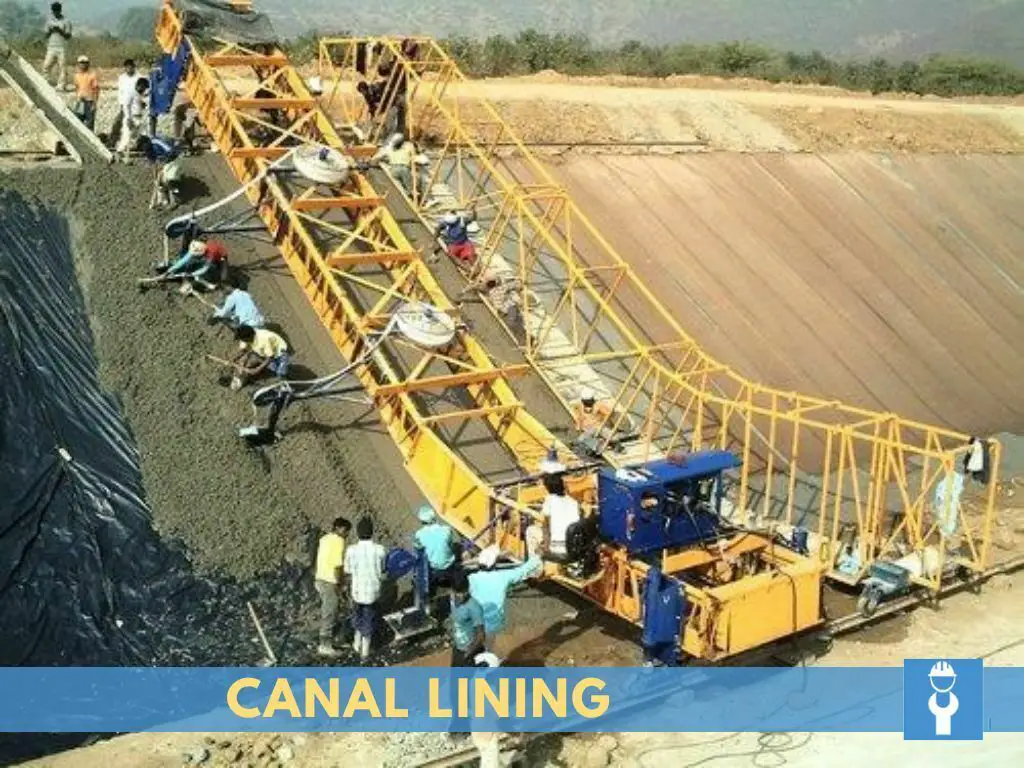

• Sophisticated construction equipment and labor is needed.

Types of Canal Lining

• Reinforced Concrete Lining

• Plain Cement Concrete Lining

• Prefabricated Cement Concrete Lining

• Shotcrete Lining

• Brick or Tile Lining

• Asphalt Concrete Lining

• Stone Lining

• Soil Cement Lining

• Compacted / Stabilized Earth Lining

• Membrane Lining

o Exposed Membrane

o Burried Membrane

Selection of Suitable Type of Lining

1. Imperviousness:

To save seepage losses and as an important anti water-logging measure, it should ensure maximum degree of water-tightness. Cement and concrete lining is more impervious than tile lining.

2. Hydraulic Efficiency:

The carrying capacity of a channel varies inversely with the value of coefficient of roughness of the lined surface. The coefficient of roughness increases with the deterioration of lined surface with the passage of time. Concrete and tile linings are hydraulically most efficient.

“Canal lining offers the solution because it helps conserve the costly impounded water otherwise lost during conveyance due to high seepage losses”

3. Durability:

The lining should be strong and durable. It should be resistant to wearing, weathering, chemical action of salts present in soil, thermal and moisture changes.

4. Structural Stability:

The lining should be reasonably stable to withstand the differential subsoil water pressure due to subsoil water and backfill getting saturated through seepage or due to sudden drawdown.

5. Economy:

The lining is justified in case the benefits occurring from it offset the first cost and subsequent maintenance and give a reasonable return on the capital investment. The lining should be economical in initial cost, repair and maintenance.

6. High Velocity:

Lining is intended to withstand maximum velocity of flow so that the section is the minimum possible.

7. Life:

The life of lining should be as intended. Cement concrete lining has the longest proved life (over 60 years) with least maintenance.

8. Weed Growth:

The lining should be in-penetrable to root of plants, entirely eliminating the possibility of weed growth to keep the flow smooth, clear and perfect.

9. Availability of construction material:

The economical lining is the one which makes use of the available construction material at or near the site.

10. Labor Strength Available:

The optimum utilization of the kind and strength of labor available for work should be possible with the type of lining selected.

11. Operation and maintenance charges:

The lining selected should require least operation and maintenance charges; easy reparability and at economical cost as in case of tile brick and precast concrete lining compared to insitu concrete lining.

12. Sub-grade:

Adaptability of the type of lining selected to the given sub-grade is of paramount importance.

13. Resistance to abrasion:

Sediment carried by canal water damages the lining by abrasion. Concrete and boulder lining are most resistance to abrasion compared to other linings.

Types of Canal Lining

Reinforced Cement Concrete lining:

Most concrete linings installed in older irrigation channels were reinforced. During recent years reinforcement has been omitted wherever possible to reduce construction cost.

Unreinforced concrete linings are to some extent susceptible to damage by hydrostatic or other pressure under the lining than reinforced concrete linings. Where unexpected hydrostatic pressures are encountered under the lining, unreinforced concrete ruptures more readily than the reinforced concrete.

The reinforced concrete lining can be justified under unusual conditions, such as high back pressures, high flow velocities in the canal, unstable sub-grade and in reaches where failure would endanger life and property outside the canal.

The main function of reinforcement is to minimize the tendency and severity of cracking and prevent separation of several parts of the concrete slab. Power channel of Ghazi Brotha Hydropower Project is RCC lined canal.

Plain Cement Concrete Lining:

Concrete linings probably constitute the best type where benefits justify their high cost. Properly designed, constructed and maintained concrete linings should have an average serviceable life of over 40 years. Some linings still in good condition are 50 to 60 years old.

Concrete linings are suitable for large and small canals, and for both high and low velocities. They fulfill practically every purpose of lining.

They are usually subject to some cracking, but cracks which permit appreciable leakage can be sealed with asphalted compounds. Costly maintenance is seldom necessary.

These are constructed by well-designed premixed cement concrete mixture of selected aggregates, Portland cement and water. The concrete mix should have enough plasticity for thorough consolidation. At the same time, it can be laid manually or by mechanical means. Hand placing is possible only in small canals and distributaries.

Concrete linings usually consist of 2 to 6 inches thick slabs placed on well prepared canal sub-grade.

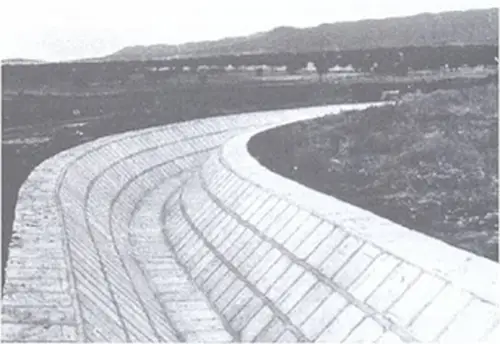

Prefabricated Cement Concrete Lining:

Canal lining with prefabricated cement concrete slabs is more suitable at places where cheap labour, aggregate and transport are easily available. This type of lining is preferred over the insitu concrete lining because of better control over mixing, moulding and curing which can be achieved in a controlled casting yard.

Prefabricated slabs are easy to place on steep side-slopes as compared to laying of cement concrete at site in similar conditions.

This takes lesser time for construction than that of in-situ concrete. Nominal reinforcement is required to avoid breakage during haulage. Operation and maintenance cost is low with an average life of 50 years.

A combination of in-situ concrete in the bed and precast slab on the sides can also be adopted with advantage. Thickness of precast slabs may vary from 2 to 2.75 inches or more.

Shotcrete Lining:

Shotcrete is a term adopted for applying cement-sand mortar under pneumatic (air) pressure. If shotcrete is used in thin layers of 1/4″ to 1/2″ on soil, it often gives trouble. A thick coat of 1.0 to 1.5 inches is durable but it is more costly than a cement concrete layer of equal thickness. Use of shotcrete on rigid but porous or deteriorated surfaces is very useful. Geocomposite liner with a 3-inch shotcrete cover is used for lining option in DRYDEN CANAL, in Wenatchee Valley Washington.

Brick or Tile Lining:

This type is commonly used if good quality tiles or bricks and cheap labor are available. The tiles/bricks should be manufactured from the soil having a clay content 10 to 20 percent and salt content of not more than 0.3 percent.

Clay tiles are very porous and are not much effective in preventing seepage losses. Brick/tiles linings have been tried on various canals in the sub-continent. The main advantages of brick/tile lining are that the bricks/tiles can be manufactured in the vicinity of the work.

No contraction and expansion joints are required and these are easy to lay and maintain. The main drawback in the manufacture of bricks/tiles is the problem of non-availability of suitable soil as most of the soils in Pakistan contain salt substantially higher than the prescribed limit. Mohajir Branch (of Thal Canal), BRBD, Lahore Branch etc are brick lined.

Asphalt Concrete Lining:

Asphalt mixed with sand and gravel, is used as a lining mixture in the same way as concrete made from portland cement. Asphalt concrete linings when properly constructed are comparable to portland cement concrete linings in many respects.

The thickness of lining varies from 2 to 4 inches. The serviceable life varies from 15 to 20 years

The advantages as compared with portland cement concrete linings include the possibility of placement even during freezing temperatures. It has better adjustment to sub-grade changes and possibility to use slightly poorer quality of aggregate. Initial cost of this type of lining is very low on account of considerable price difference between asphalt and portland cement. Seepage losses can be reduced to as low as in the case of portland cement concrete lining but these will increase considerably after the weed growth over the time with cracks development.

Stone Lining:

Lining of stone masonry can be applied in areas where suitable materials, such as stone are available. The construction of this type is relatively slow and the cost of labour is the major expense. Seepage losses may be very high if the stones are not laid in mortar. This type is more suitable for main canals under scouring action or in locations where there is movement of gravel along the bed.

Soil-Cement Lining:

Soil-cement linings are constructed with mixture of sandy soil, portland cement and water. This mixture hardens to a concrete like material. The life of this type of lining varies from 10 to 12 years but if properly constructed and maintained then it may serve up to 20 years or so. The thickness of lining varies from 4 to 6 inch. Initial cost of soil cement lining is low as compared to others.

It is suitable for the areas where good sandy soils are available within or in the vicinity of the project area. The seepage losses can be reduced to that of the cement concrete lining, if proper mixing and compaction is done. It however affords less structural stability.

Compacted / Stabilized Earth Lining:

Earth lining is composed of compacted earth, mixed with some chemicals which improve the stabilization of the earth. This is comparatively the cheapest type.

Thickness of lining varies from 12 to 24 inches for bed and even more for steep slopes.Seepage losses are more and the structural strength is also poor. It is resistive to weed growth. Deep cracks develop on the surface, if the canal is dry. It requires top-most quality of compaction so that moisture content may not increase or decrease. The average life of this type of lining is about 10 years.

Exposed Membrane Lining:

Exposed membranes include thin membranes of asphalt, plastics and synthetic rubber. They possess low permeability, but have no structural strength. Seepage losses mainly depend upon weed growth and other mechanical damages as well as weathering. The life of this type is only a few irrigation seasons.

Due to shorter life the economic use of exposed membrane lining is limited to special cases, such as temporary emergency linings, short sections less vulnerable to damages etc.

Buried Membrane Lining:

A buried membrane canal lining consists of a relatively thin and impervious water barrier covered by a protective layer which forms the water-carrying prism. The asphalt spray, plastic film, bentonite and prefabricated asphalt are used as construction material for membranes. Since the protective cover does not get properly attached with the plastic sheet, sloughing and slipping of earth on the sides usually take place. The minimum side slope recommended is 2:1.

The life of the lining depends largely on erosion resistance of cover material. Skilled personnels are required; it can be transported easily along the canal. Suitability of excavated soil as cover material is important for economic reasons.

my project pcc linning

my project pcc linning

what concrete mix design used in pcc small canal?????

what concrete mix design used in pcc small canal?????

Based on very usual cases the concrete can be of 1:3:6 for small canals.

Based on very usual cases the concrete can be of 1:3:6 for small canals.

Nice post. A very informative. Thanks.

Nice post. A very informative. Thanks.