The wood timber that is suitable for construction is obtained from trees that will measure 0.6m in girth or more. There are different types of woods available for various purposes. The woods that is available for construction is called as timber.

As strength and durability is the major concern in construction, the timber as a construction material is less demanded in civil engineering field. The timber used in current construction industry is hence subjected to various levels to treatment, seasoning and preservation thus making it suitable for durable and safe structures.

Uses of Timber in Construction

Different uses of timber in construction are as follows:

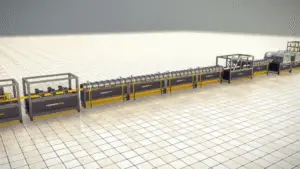

- Timber is used as sleepers, coaches in railway construction.

- Timber used in making furniture.

- Timber used in the formwork construction.

- Timber used in making trusses, rafters, piles, arches , partition walls, poles, beams etc

Advantages of Timber Construction

- The timber sections can be easily joined with the help of carpentry tools. All types of connections are possible with timber.

- The timber sections can be easily cut and sawn easily. Conversion of timber to any shape or size is possible.

- Timber can be used as a load bearing structure and a non load bearing structure.

- When the weight to weight factor is concerned, the timber will have higher strength compared with the opposite equally weighed material.

- Timber construction is cheap and economical in nature.

- The amount of wastage in timber construction is very less.

- The timbers will posses higher durability, if it is properly seasoned and treated.

- The thermal comfort guaranteed by timber is very high as timber is non-conductor of sound and heat. This construction also guarantees high insulation for sound and noise.

- The structural units made out of timber are light in weight.

- Timber has high resistance towards corrosion. This makes it best suitable for marine construction.

- The timber material is easily available. The transportation of the same is an easy process.

- Many variations in timber material can be made in order to match with the present demand and aesthetics in new construction world. These include veneer materials, plywood and laminates.

- The timber material can be easily altered and variations are brought very easily.

- When compared with the production of steel and aluminium, the timber is highly energy efficient.

- Heavy construction of timber will give a massive and royal loo to the structure.

Disadvantages of Timber in Construction

The limitations of timber are as follows:

- Wood has the possibility to undergo cracking or creep if not subjected to proper seasoning.

- Improper preservation of timber will result in decay of the material.

- The timber once constructed will demand for proper maintenance

- The timber is not a fire resistant material.

- The site areas that have cyclic weather conditions cannot efficiently use timber construction.

- For areas that are prone to natural calamities, the material won’t suit good.

- Timber material will be costly if it is not available locally.

- Timber construction will result in deforestation.

Timber Characteristics

A good quality timber is defined by certain good quality properties that will enable good construction. These qualities depend on the:

- Type and maturity of the tree

- The Nature of soil

- The time of falling of the tress

- The seasoning methods followed by the tree

- The type of preservation followed

- The process of preservation

The major qualities of good timber in construction are described below.

1. Colour and Appearance of good timber: A good timber material must possess dark colour. Low strength of the timber can be understood from its light colour. For this the wood taken must be from the hard wood. This hard wood has to be free from the sap. Uniformity in colour has to be possessed by the wood.

In appearance, the wood must have a hard and shiny surface. Once the timber is planed, the surface must be smooth and bright in colour. Having a dull appearance shows all signs of defects in it.

2. Defects: The timber used for the construction has to be free from defects like blemishes, flaws, shakes, knots etc.

Like Us on Facebook!

3. Timber Resistance and durability: The timber has to be resistant towards the action of fungi, insects, alkalies, physical agencies and mechanical agencies.

Subscribe Us on YouTube!

4. Weight of Timber: The weight and the density of timber have to be more. This will reflect a sound timber material.

5. Fibres in Timber: The timber is made of fibres in thousands. These fibres have to be straight and compact in nature. All the fibres within have to be firm and adhesive to each other.

6. Elasticity of Timber: Elasticity property of the timber material is essential for the construction of goods, trusses, shafts etc.

7. Mechanical Wear of Timber: The mechanical wear or abrasion resistance of the timber will help it to stay long when used in high traffic areas, as pavements or wooden floors.

8. Hardness of Timber: The resistance against penetration of any other material into the timber is gained by the hardness property. The chemicals that are present in the heart wood will impart hardness to the material. The density of the wood also defines the hardness of the timber material.

9. Shock Resistance of Timber: The timbers have to be resistant towards undesirable shocks. This is gained by shock resistance property.

10. Shape of Timber: All the preparation process of the timber must not bring any change in shape of the material. It must not undergo any change in shape even after it is subjected to structural use. Change in shape means either warping, expanding, splitting or swelling of the timber wood.

11. Timber with Good Finish and Polish: The timber is finally subjected to final finish and polish. The material must have the ability to take good polish when used in the application of window doors, furniture items. The surface of the timber must have the ability to receive the paint properly.

12. Odour and Sound: The freshly cut wood will have a sweet smell and an unpleasant smell shows the timber have started to decay. A ringing sound made by two pieces of wood will show that it is sound wood.

13. Strength of Timber: A good quality wood must possess strength to carry all types of loads. It must carry all the direct, shear and bending stress in order to behave as a sound beam, column, post, joist and a rafter.

14. Permeability of Timber: The permeability in case of timber, is the possibilities of penetration of water. Good quality timber must be impermeable in nature. The permeability is more along the direction of fibre orientation than on perpendicular direction.

15. Structure of Timber: The timber structure has to be uniform in nature. The timber cross sections consist of annular rings and medullary rays. The annular rings must be regular for good quality wood. This will have hard and compact medullary rays

16. Workability of Timber: Good timber must be able to cut easily, planed and smoothened easily. During the process of sawing, the teeth must not undergo clogging.

Best Practices For Use

From framing timber to wooden furniture sets, the popularity of this material in engineering and construction is undeniable. But to ensure its integrity, engineers must uphold the following best practices when using it:

- Select timber species appropriate for your specific project’s requirements in terms of strength, durability, and appearance. Preferably, they are ethically sourced.

- Treat timber with appropriate preservatives to protect it from moisture, rot, and insect infestations, especially for outdoor or ground-contact applications.

- Account for factors such as load-bearing capacities, spans, connections, and potential movements of timber components.

- Inspect timber for defects, knots, splits, and other imperfections before use. Reject or repair compromised pieces.

- Use only well-dried and seasoned timber to prevent excessive shrinkage or warping after construction.

- Use appropriate joinery techniques that ensure solid, stable connections between timber components. Choose suitable fasteners, such as screws, nails, and bolts, and follow manufacturer recommendations for installation.

- Apply fire-resistant coatings or treatments to timber elements as local building codes and regulations require.

- Implement a regular maintenance schedule to promptly inspect and address any issues, such as checking for signs of decay, damage, or wear.

- Foster open communication between architects, engineers, contractors, and other stakeholders to ensure everyone is on the same page regarding design, execution, and safety.

Work with the right contractors, suppliers, and distributors for the best use of timber for construction. That ensures the quality and success of engineering projects.