In our modern world, where electrical equipment is an integral part of everyday life, ensuring electrical safety is of paramount importance. Faulty or damaged electrical appliances can pose serious risks such as electQrocution and fires. Test and tag training is a specialized program designed to equip individuals with the necessary skills and knowledge to inspect, test, and tag electrical equipment, ensuring a safe environment in homes, workplaces, and public spaces. In this comprehensive guide, we delve into the importance of test and tag training and its role in safeguarding electrical safety.

Electrical safety is of paramount importance in both residential and commercial settings. To prevent accidents and ensure the well-being of individuals, electrical equipment must be regularly inspected and tested for potential hazards. Test and tag training is a vital aspect of this safety protocol, equipping professional with the necessary skills and knowledge to perform these critical tasks.

What is Test and Tag Training?

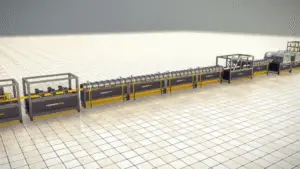

Test and tag training is a specialized program designed to educate individuals on how to inspect, test, and tag electrical equipment. The process involves using specialized testing equipment to examine the integrity and safety of electrical appliances, extension cords, power tools, and other electrical devices.

This training is particularly important for personnel who work in industries where electrical equipment is regularly used, such as construction, manufacturing, office environments, events management, and other commercial sectors. Additionally, landlords and property managers can also benefit from this training to ensure the safety of their tenants.

The Importance of Test and Tag Training

Electrical Safety Compliance: Test and tag training helps individuals understand and adhere to the relevant electrical safety regulations and standards set by governing bodies. In many countries, electrical equipment testing and tagging are required by law, and failure to comply can result in penalties and liabilities.

Accident Prevention: Faulty electrical equipment can cause electrocution, fires, and other accidents. Regular inspection and testing help identify potential hazards and prevent accidents before they occur.

Risk Reduction: By identifying and addressing potential risks associated with electrical equipment, test and tag training reduces the risk of injury or property damage, thereby minimizing financial and legal liabilities.

Maintaining Workplace Productivity: Ensuring that electrical equipment is safe and operational reduces the likelihood of equipment failure and downtime, leading to improved workplace productivity.

Increased Equipment Lifespan: Regular testing and tagging can help identify issues that might contribute to the premature failure of electrical equipment. Addressing these issues promptly can extend the lifespan of the equipment and reduce replacement costs.

Like Us on Facebook!

What Does Test and Tag Training Cover?

Test and tag training courses cover a wide range of topics to provide participants with a comprehensive understanding of electrical safety practices. Some of the key topics typically covered include:

Subscribe Us on YouTube!

Electrical Safety Regulations: Understanding relevant electrical safety standards and regulatory requirements specific to the region.

Risk Assessment: Identifying potential hazards associated with different types of electrical equipment and situations.

Testing Procedures: Learning how to correctly use testing equipment to assess electrical equipment for safety and integrity.

Visual Inspection: Conducting a visual inspection of electrical equipment to identify obvious defects or damage.

Testing Techniques: Performing various electrical tests, including earth continuity, insulation resistance, and polarity testing.

Record Keeping: Properly documenting test results, equipment details, and inspection dates for compliance purposes.

Tagging Procedures: Applying appropriate tags to indicate the status of the equipment and the date of the last inspection.

Who Should Attend Test and Tag Training?

Test and tag training is suitable for various individuals, including:

Electricians and Electrical Contractors: Enhancing their existing electrical knowledge with specialized testing skills.

Safety Officers and Managers: Acquiring the expertise to implement and oversee electrical safety protocols in the workplace.

Building and Facility Managers: Ensuring the safety of occupants by regularly inspecting electrical equipment.

Small Business Owners: Equipping themselves with the necessary skills to comply with safety regulations and protect their employees and customers.

Section 1: Understanding Test and Tag Training

1.1 What is Test and Tag Training?

– Definition and objectives of test and tag training.

– The importance of regular inspection and testing of electrical equipment.

1.2 Legal and Regulatory Requirements

– Overview of electrical safety regulations and standards.

– How compliance with regulations reduces liabilities and promotes safety.

Section 2: The Significance of Electrical Safety

2.1 Preventing Electrical Accidents

– Understanding the potential hazards of faulty electrical equipment.

– Case studies illustrating the consequences of electrical accidents.

2.2 Risk Reduction and Mitigation

– Identifying common risks associated with different electrical appliances.

– Strategies for minimizing risks and ensuring electrical safety.

Section 3: The Test and Tag Process

3.1 Visual Inspection

– Conducting a thorough visual examination of electrical equipment.

– Identifying visible defects and signs of damage.

3.2 Electrical Testing Techniques

– Earth continuity testing: Ensuring proper grounding of equipment.

– Insulation resistance testing: Verifying the integrity of electrical insulation.

– Polarity testing: Confirming correct wiring connections.

3.3 Testing Equipment and Tools

– An overview of commonly used testing instruments.

– How to effectively use testing equipment for accurate results.

Section 4: Practical Application of Test and Tag

4.1 Creating a Test and Tag Schedule

– Developing a systematic testing and tagging plan.

– Determining the frequency of inspections based on equipment type and usage.

4.2 Record Keeping and Compliance

– The importance of maintaining accurate records of test results.

– Implementing a proper record-keeping system for compliance purposes.

Section 5: Test and Tag Training for Various Industries

5.1 Construction and Manufacturing Sectors

– Addressing electrical safety concerns in industrial settings.

– Best practices for testing and tagging in construction and manufacturing environments.

5.2 Office Spaces and Commercial Establishments

– Ensuring electrical safety in offices and commercial buildings.

– Training employees to identify potential hazards and report issues.

5.3 Events and Public Spaces

– Safety protocols for temporary electrical setups in events and public gatherings.

– Training event organizers and staff in electrical safety measures.

Conclusion:

Test and tag training is not only a legal requirement but also an ethical responsibility to ensure the safety of individuals and property. By providing comprehensive knowledge about electrical safety and practical skills for testing and tagging, this training equips individuals and professionals to prevent accidents, reduce risks, and maintain a secure environment. Emphasizing the importance of compliance with electrical safety regulations, this guide underscores the significance of test and tag training in safeguarding our digital frontier.