Shear strength is the ability of soil to withstand forces that may cause it to fail during sliding or shearing is known as shear strength. It is a measure of the soil’s resistance to these pressures. The balance between the applied shear force and the resistance offered by cohesion and friction determines the shear strength of the soil. The soil will fail and experience sliding or shearing if the applied shear force is greater than the resistance of the soil.

The shear strength of soil is primarily composed of the cohesion, friction and normal stress. Cohesion is the inherent bond between the soil particles. It is the force that holds the soil particles together.

Cohesion is a measure of the strength of the bonds between soil particles and is typically influenced by the type of soil, the water content, and the degree of compaction. Similarly, friction is the resistance of soil to sliding along its plane. It is the force that opposes sliding between soil particles.

Friction is influenced by the type of soil, the size and shape of the soil particles, and the degree of compaction. However, normal stress is the stress perpendicular to the soil’s surface. It is a measure of the weight of the soil and the loads applied to it. Normal stress affects the shear strength of soil by including cohesion and friction.

Direct Shear Test:

The direct shear test is a laboratory test use to assess the soil’s shear strength. It entails sandwiching a soil sample between two parallel plates and applying a shear force along the sample’s plane. The shear strength of the soil is determined by finding the greatest shear force that the soil can bear before failing.

The shear strength is then used to assess slope and embankment stability, construct foundations and retaining walls, and anticipate soil behavior during earthquakes and other geotechnical events. The direct shear test offers useful information on the behavior of soil under shear loads and may be used to forecast how the soil will respond to shear stress in the field.

Also Read: FDD full form in Civil Engineering

Objective:

The direct shear test is designed to assess soil shear strength properties such as shear strength, shear strength envelope, and residual shear strength. The direct shear test is frequently used in geotechnical engineering and soil mechanics to determine soil shear strength. This data is used to plan and build safe and stable structures such as foundations, retaining walls, and slopes, as well as to forecast soil behavior during earthquakes and other geotechnical occurrences. The test provides the following information:

• Shear strength is a measure of how much shear stress a soil can tolerate before failing. It allows you to assess the soil’s stability and resistance to sliding or shearing forces.

Like Us on Facebook!

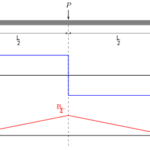

• A shear strength envelope is a graph that depicts the connection between shear stress and normal stress on a soil sample. It describes the behavior of the soil under various loading circumstances.

Subscribe Us on YouTube!

• The residual shear strength is the shear strength that remains after shear failure in the soil. It describes the soil’s stability after a collapse and its capacity to withstand loads.

Apparatus:

The apparatus used in a direct shear test typically includes the following components:

- Shear box: The shear box is a rectangular box that holds the soil sample. It is usually made of metal or plastic and has two parallel plates for applying the shear force.

- Loading frame: The loading frame is used to apply the shear force to the soil sample. It consists of a hydraulic jack or a motorized screw jack that can apply a controlled and uniform shear force to the soil sample.

- Loading platens: The loading platens are the plates that apply the shear force to the soil sample. They are usually made of metal or a hard, wear-resistant material and are held in place by the loading frame.

- Dial gauges: The dial gauges are used to measure the shear force and normal force acting on the soil sample. They are mounted on the loading platens and provide continuous readings of the shear and normal stresses.

- Porous stones: porous stones are placed between the loading platens and the soil sample to provide drainage and prevent the buildup of pore water pressure.

- Soil sample: The soil sample is a representative sample of the soil being tested. It is typically taken from a field or a laboratory-prepared sample. The size and shape of the soil sample will depend on the type of test being performed.

Sample Preparation:

- An undisturbed sample must be sufficient enough to give at least three identical specimens.

- Make the specimens such that there is little moisture loss.

- Trim large specimens to fit the trimmer’s length and the inside diameter of the direct shear mechanism.

- To prevent changing the natural structure of sensitive soils, extreme consideration must be exercised when preparing undisturbed samples.

- Determine the specimen’s initial mass for use in subsequent computations of the specimen’s initial moisture content.

- When using compacted soil samples, they must fulfill the required moisture density criterion.

Procedure:

The procedure for a direct shear test typically involves the following steps:

Also Read: Determine Liquid Limit of Soil Specimen by Casagrande Method

Preparation of soil sample:

A soil sample is prepared by compacting the soil into the shear box or by cutting a block of soil from a prepared sample. The soil sample should be representative of the soil being tested and should be uniform in composition and density.

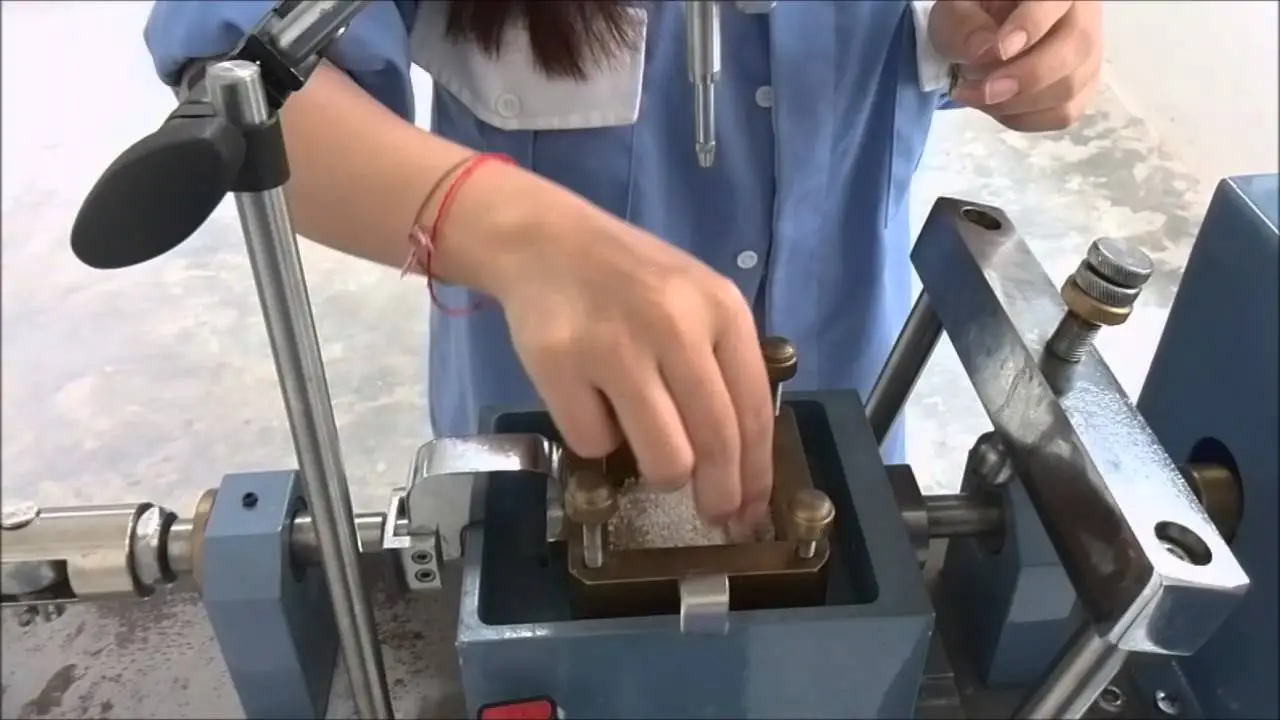

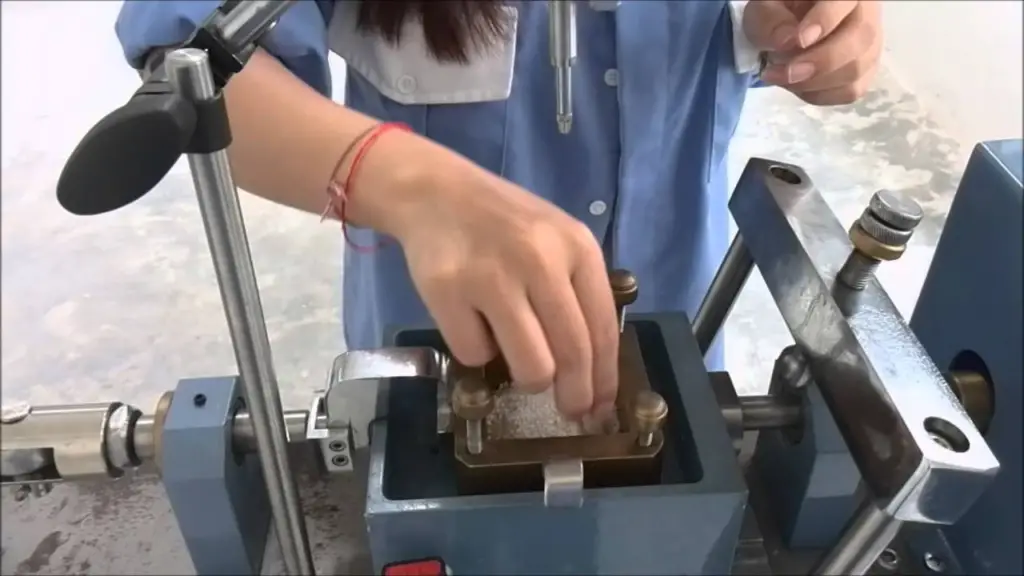

Placement of sample in the shear box:

The soil sample is placed between the two parallel plates of the shear box. The loading platens are then placed on top of the soil sample and the dial gauges are mounted on the loading platens.

Application of normal stress:

Normal stress is applied to the soil sample by adjusting the hydraulic jack or screw jack. The normal stress is typically applied in increments and is held constant during the shear test.

Application of shear stress:

By moving the loading metal plate relative to each other, shear stress is delivered to the soil sample. Shear force is generally delivered in increments and maintained constant during each increment.

Observation of soil behavior:

The soil behavior is noticed when a shear force is applied. The soil’s reaction to shear stress is recorded and utilized to calculate shear strength and shear strength envelope.

Calculation of shear strength:

The maximum shear stress that the soil can withstand before failure is used to compute shear strength. The shear strength envelope is shown graphically as a graph of shear stress vs normal stress. The behavior of the soil after failure may also be used to calculate the residual shear strength.

Precautions:

1. Before beginning the test, place porous stone with grippers at the top and bottom of the shear box.

2. After inserting the shear box cart into the device, completely fill the cart with water and allow the sample to get saturated.

3. The remaining steps are the same as those previously mentioned.