Asphalt is basically combination of bitumen and aggregate, the surface of aggregates are applied with bitumen and then bitumen acts as a binding agent that makes it a solid and firm material called asphaltic concrete.

Like we all know about traditional Portland cement concrete that its properties and strength is largely dependent on the amount and proportion in which the constituents are mixed, same is the case here in asphaltic concrete.

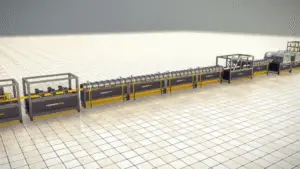

|

| Picture Credits : hubspot.net |

What is Job Mix Formula (JMF)

The mix design of Aspahltic concrete is carried out by Marshall Mix Design and end result of a successful mix design is a recommended mixture of aggregate and asphalt binder. This recommended mixture, which also includes aggregate gradation and asphalt binder type is often referred to as the job mix formula (JMF)

To know more about Marshall Mix Design Process and how job mix formula is to be determined Click here

Properties of Ideal Asphaltic Concrete Mix

The main objective of the Job Mix Formula, Mix Design Method, Marshall Mix Design method is to determine an ideal and optimum asphalt mix that has following properties :-

1. Resistance to permanent deformation: The mix should not distort or be displaced when subjected to traffic loads. The resistance to permanent deformation is more important at high temperatures.

2. Fatigue resistance: the mix should not crack when subjected to repeated loads over a period of time.

3. Resistance to low temperature cracking. This mix property is important in cold regions.

4. Durability: the mix should contain sufficient asphalt cement to ensure an adequate film thickness around the aggregate particles. The compacted mix should not have very high air voids, which accelerates the aging process.

Like Us on Facebook!

5. Resistance to moisture-induced damage.

Subscribe Us on YouTube!

6. Skid resistance.

7. Workability: the mix must be capable of being placed and compacted with reasonable effort.

8. Low noise and good drainage properties: If the mix is to be used for the surface (wearing) layer of the pavement structure.