Saying of Timber may be defined as

“To cut the logs into various formations into pieces is called sawing.”

Purpose of sawing

The logs (trees after felled) if not cut for a long time would results in circumferential shrinkage because of drying of moisture from the outer most part and less dryness in the inner part. i.e. the outer most rings shrink more as compared with inner rings. As a result star shakes or cracks would appear on the surface of log and would narrow as one goes inwards.

Methods of Sawing

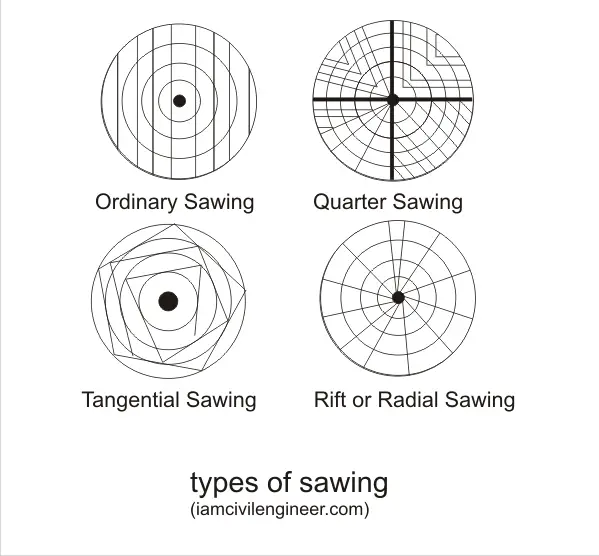

There are four basic methods of sawing.

i) Ordinary sawing

ii) Quarter sawing

iii) Tangential sawing

iv) Rift or Radial sawing

Ordinary Sawing

It is the most economical, cheapest and is widely used method of sawing. In it only long parallel planks are cut. Because the inner portion is heart wood which is hard and outer portion is sap wood which is soft thus after dryness there will be unequal shrinkage, thus the planks are liable to wrap and twist.

Quarter Sawing

In Quarter sawing the logs are cut or sawn in quarter and is then cut in such a way so as to bend in transverse direction. This method is adopted when no distinct modullary rays are present and gives very fine figure wood.

Rift or Radial Sawing

In this method logs are sawn parallel to modulary rays and perpendicular to annual rings. This method gives least shrinkage but most wasteful. This method gives most decorative works in which medullary rays are marked, and least shrinkage is because of the property of medullary rays to resist shrinkage.

Tangential Sawing

If annual rings are well formed and medullary rays are not well formed than tangential sawing is used. In this method cuts are made tangent to the annual rings. Planks obtained by this method wraps too much and must not be use for costly works. Such planks are not suitable for flooring.