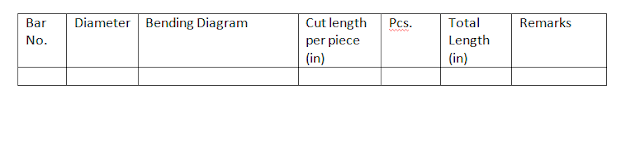

Bar Bending Schedule or BBS is actually a detailed tabulated worksheet showing the particulars of reinforcing bars as needed in reinforcement drawings of a structure. The phrase “Bar Bending” is so because at the steel yard where different types of reinforcement are cut and bent this table is used as a reference to bend the reinforcement bars in desired and required shape and sizes.

|

| What is Bar Bending Schedule? |

What information a bar bending schedule has?

Bar Bending Schedule is expected to contain all the important information and summarizes in tabular form. A good bar bending schedule must contain the following information :-

- Bar Mark No.

- Cut Length

- No. of Pieces

- Bar Cut Shape

- Bar Diameter

Therefore now we are able to prepare a Template of a bar bending schedule; a typical bar bending schedule would be like this :-

|

| A typical Bar Bending Schedule Table |

Now from here you might be asking one question that what actually is the need of this tedious job of preparing Bar Bending Schedule.

What is the need of Bar Bending Schedule?

The simplest answer for this question would be that money matters a lot and reinforcement bars, in any project, takes a healthy share of the financial term of the project. Therefore in order to purchase material we need an estimate which should be near-to-actual during execution, this estimate may differs from engineer estimate which is only on the basis of experience and is only taking construction or bidding tender drawings as reference which are general and typical.

Thus with the help of Bar Bending Schedule you would have a clear figure about how much reinforcement you need to purchase of various diameters. After purchase the reinforcement the next phase is to cut and bend.

This cutting and bending must follow the bar shape shown in the bar bending schedule, thus before execution bar bending schedule is a must-to-have document at site. It is a good working technique because we cannot bear any error or mistake during this cutting and bending which otherwise will cause financial problems for all concerned.

The next phase after project execution is witness of the quantity by engineer at site as per drawings and verification of this quantity for further payment and financial steps. Engineer during steel fixing check the rebar as per the shop drawing and ensure it matches the bar bending schedule duly approved by the quantity and measurement engineer.

Like Us on Facebook!

Thus for the payment of the contractor by client this document is also needed.

The contractor actually submits a document called Quantity Witness Report (QWR) to the engineer having attached all the documents required like, reinforcement approved inspection requests, approved structural shop drawings, approved bar bending schedules. This is then verified by the engineer.

Subscribe Us on YouTube!

What are the qualities of a good bar bending schedule?

It is always ensured that the person preparing the bar bending schedule must have a solid site execution experience. The rebar designation and cut length must be carefully selected as it will be the defining point for the scrap which will be remained after cutting and bending.

To know more about what are the qualities of a good bar bending schedule follow below link :-

How to define a good bar bending schedule?