Whether you’re a seasoned woodworker or a DIY enthusiast, there’re at times when you start wondering “how to size an LVL beam”. That’s where LVL Span calculator comes handy.

For a safe structural system, you got to have the right size of the LVL beams. The span that the beam can safely have depends on various factors including the load applied and the overall usage of the structure. But for a rough estimate, you can relate the span with the size of the beam using thumb rules.

So, in our today’s blog I’ve tried to delve in; how to size LVL beams and what are some factors one must consider before commenting on the LVL beam strength:

What is an LVL Beam?

A high Strength structural engineered wood normally made up of plywood and composed of thin sheets which are integrated together using stronger glue is called laminated veneer lumber or LVL. It is widely used in different construction projects and available in a variety of sizes and thicknesses. Most contractors and estimators consider LVL while delivering precise and accurate Construction Estimating Services. The typical usage of LVL includes; boards, beam rim boards, edge-forming materials, beams, trusses, and skateboards.

In this unique article, we embark on a fascinating journey through the world of LVL, exploring its production procedure, distinguishing features compared to plywood, beam sizes and support, helpful calculators, and even its practicality and cost. Buckle up and prepare to be amazed!

Production Procedure: Crafting LVL Magic

Laminated Veneer Lumber (LVL) is no ordinary timber. It’s a marvel created through a meticulous production process that harnesses the power of wood veneers. The process begins with carefully selecting and peeling thin wood veneers from logs. These veneers are then dried and coated with adhesive. After that, these veneers are layered together, with every single layer is positioned at 90 degrees to the previous layer.

The stack of veneers is pressed and heated, forming a solid, durable panel of LVL. The end result is an incredibly strong and versatile wood product that defies the limits of conventional lumber.

Differences between LVL and Plywood: Unveiling the Distinctions

While LVL and plywood share similarities, they are not interchangeable. Here’s a quick rundown of the key differences:

- Composition: LVL is made from stacked veneer layers bonded together, while plywood consists of thin layers of wood glued together with their grains oriented in alternating directions.

- Strength: LVL boasts exceptional strength, allowing for longer spans and heavier loads compared to plywood.

- Consistency: LVL’s manufacturing process ensures consistent material properties throughout the entire board, providing reliable performance in structural applications.

- Edge Performance: LVL’s solid construction means its edges can be exposed without compromising its integrity, whereas plywood edges may require additional treatments for aesthetics.

LVL Beam Size: The Power of Dimensions

When it comes to LVL beams, size matters. Determining the appropriate beam size is crucial for structural stability and load-bearing capacity. The optimal LVL beam size depends on several factors:

Like Us on Facebook!

- Span Length: The distance between the supports affects the required beam size. Longer spans necessitate larger beams to withstand the load.

- Load Requirements: Consider the expected loads the beam will bear, such as live loads (e.g., furniture, people) and dead loads (e.g., the weight of the structure itself).

- Building Codes: Comply with local building codes and regulations that prescribe minimum beam sizes based on span and load requirements.

LVL Beam Size Calculator: A Calculated Approach

To simplify the process of determining the ideal LVL beam size, a handy calculator can come to the rescue. Beam size calculators, available online and as software tools, consider span lengths, load conditions, and other parameters to recommend the most suitable beam size. These calculators provide engineers, architects, and even DIY enthusiasts with a time-saving solution, ensuring their LVL beams can withstand the test of time.

Subscribe Us on YouTube!

LVL Span Size Calculator: Bridging the Gap

Similar to the beam size calculator, the LVL span size calculator assists in determining the maximum span a particular LVL beam size can effectively support. By inputting the desired beam size, load conditions, and other relevant factors, this nifty tool can estimate the safe span length. No more guessing games or compromising structural integrity!

How to Calculate the Size of LVL Beam You Need: A Step-by-Step Guide

Now, let’s dive into the art of calculating the size of an LVL beam you need:

- Determine the span length.

- Assess the expected loads, including live and dead loads.

- Consult local building codes to ensure compliance.

- Utilize an LVL beam size calculator or consult a structural engineer for professional guidance.

- Select the appropriate LVL beam size based on the calculations.

Double-check your calculations and consult a professional if needed.

Usage and Cost of LVL Beam: Pragmatic and Cost-Effective Solutions

Laminated Veneer Lumber (LVL) beams have found their place in numerous applications, including residential and commercial construction, industrial projects, and even architectural masterpieces. The benefits of using LVL beams are plentiful:

- Exceptional strength and load-bearing capacity.

- Consistent material properties throughout the entire board.

- Versatility in structural designs and longer spans.

- Dimensional stability and resistance to warping or twisting.

- Cost-effectiveness, thanks to reduced waste and optimized strength-to-weight ratio.

While LVL beams may have a slightly higher upfront cost compared to traditional lumber, their long-term benefits and durability make them a wise investment for any construction project.

Laminated Veneer Lumber (LVL) beam sizes

Beam Length: The size of beam may vary and depending upon the manufacturer. The available lengths are 44, 40, 36, 32, 28, 24 feet and upon some special assignment the size up to 60 feet are manufactured. Typical depth of beam is 5-1/2 to 24 inches.

Beam Thickness:

The standard thickness ranges from 1-3/4 to 7 “inches. For different combinations it is available as;

- 4 (ply) = 7 “inches thick

- 2 (ply) = 3-1/2” inches thick

- 1 (ply) = 1-3/4” inches thick.

Beam length:- LVL beam length are generally available in 24, 28, 32, 36, 40 and 44 feet with special order up to 60 Feet. Generally you can find LVL beams in a 4-foot increments. It can be customized according to your requirement. More than 60 Feet there is difficulty in transportation and handling.

Beam Depth: The available depths of LVL Beams are 23-7/8 inches, 20 inches, 18-3/4 inches, 18 inches, 16 inches, 14 inches, 11-7/8 inches, 11-1/4 inches, 9-1/2 inches, 9-1/4 inches and 7-1/4 inches.

How do I determine what size LVL beam I need?

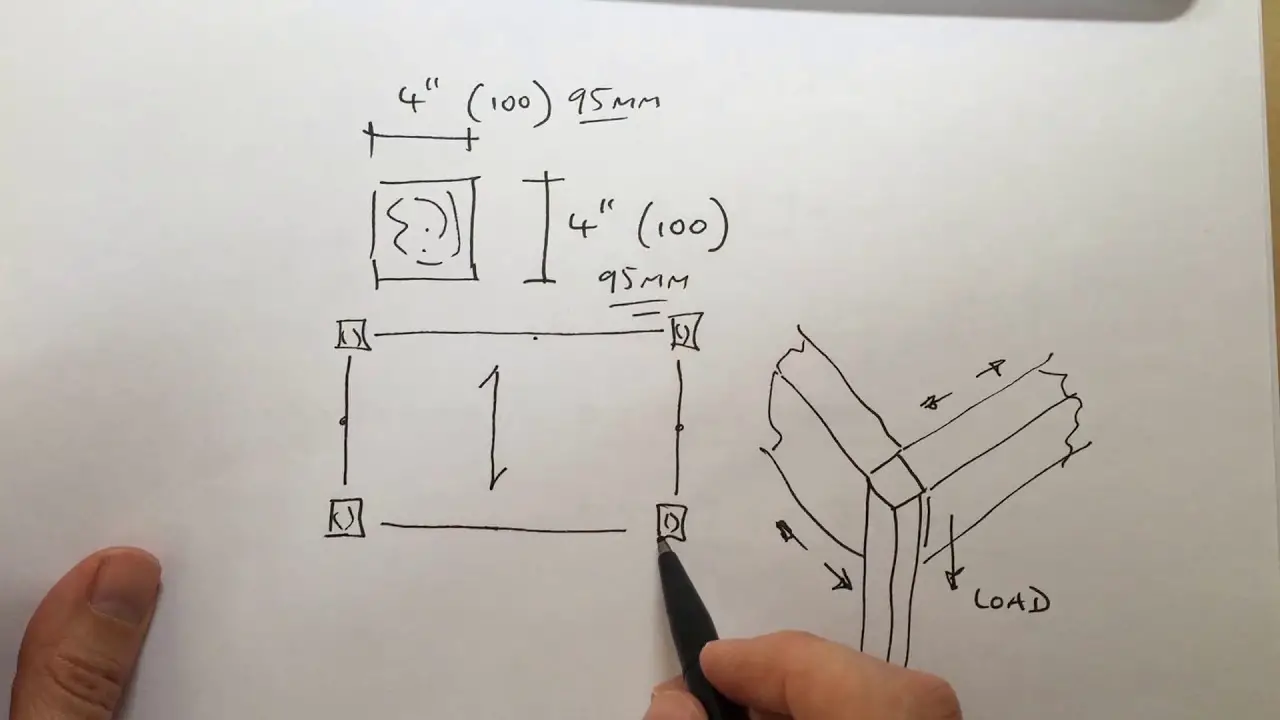

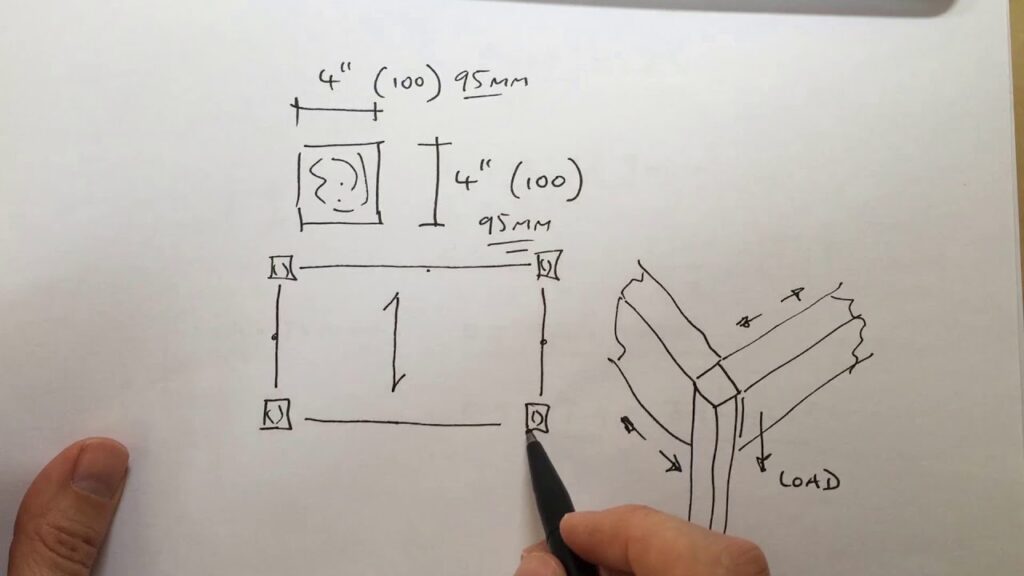

In order to calculate the size of LVL Beam, the depth is calculated based upon the thumb rule as depth of manufactured beam divided by span by 20 in inches and accordingly width is calculated as 1/3 or ¼ of its depth. For example 30 foot long LVL beam should be 12 inches deep (30×12)/30 = 12 inches

Beam Calculator of LVL

The beam width is designed based upon on the fact that a typical width of LVL Beam ranging from 1-3/4 to 3-1/2 inches. The increase in width can be achieved by the laminating sheet in multipoles of 40 mm or 1-3/4 inches. The beam width should be taken as ¼ to 1/3 of depth of beam.

LVL Beam Calculations:- .

In order to calculate the beam depth and width as per the thumb rule take this example.

Span of LVL Beam = 20 ft

Depth of Beam as per thumb rule = (20 x 12) / 20 = 12 inches

Width of Beam = 12/4 = 3 inches

Hence one need 12 inches thick LVL beam or 3-1/2 “ x 11-7/8” size up to span of 20 ft.

The Cost of LVL Beam

The cost per linear foot of LVL is around 3-12 ($) dollars and the installation cost per foot is 50-200 dollar and overall the total cost comes out to be 800-2500 ($) dollars. The cost of LVL beam having 24 Ft span is around 72 to 288 ($) dollars. Similarly, the cost of LVL beam having span length of 30’ is 90 to 360 ($) dollars. The cost of LVL beam having span length of 20’ is 60 to 240 ($) dollars.

The Span of LVL beam

Due to its strength an LVL beam can span upto 60’ and is stronger than traditional lumber. Normally, the span of LVL beam starts from 24 ft and goes upto 44 feet with a 4 foot increment. The thickness of LVL beam is between o1 ply thickness 1-3/4 inches and 4 ply thickness 7 inches.

The Cost of LVL Beam having different Sizes

On an average the cost per linear foot of LVL beam is between 3-12 ($) dollars. So, LVL beam with varying sizes the cost per linear foot is calculated as below:

Cost/price of 24 ft LVL beam = 24 x 3 = 72 ($) or 24 x 12 = 288 ($)

Cost/price of 14 ft LVL beam = 14 x 3 = 42 ($) or 14 x 12 = 168 ($)

Cost/price of 16 ft LVL beam = 16 x 3 = 48 ($) or 16 x 12 = 192 ($)

Cost/price of 40 ft LVL beam = 40 x 3 = 120 ($) or 40 x 12 = 480 ($)

Cost/price of 26 ft LVL beam = 26 x 3 = 78 ($) or 26 x 12 = 312 ($)

Cost/price of 28 ft LVL beam = 28 x 3 = 84 ($) or 28 x 12 = 336 ($)

Conclusions:-

An engineered lumber product that utilizes thin wood in multiple layers assembled with adhesives is called LVL beam and is used typically in rim board, beam, headers and edge-foaming materials.