GFRP rebar has transformed the construction sector. With the continuously growing attention to construction projects’ sustainability, the industry is turning to new solutions to overcome the limitations of traditional reinforcement.

Industry participants study the GFRP rebar production sector and its key players, FRP rebar equipment manufacturers. That is why forward-thinking investors explore new opportunities in this promising market.

Infrastructure Challenges Open New Market Opportunities

The global infrastructure faces unprecedented challenges that composite materials can address.

- The aging structures require more and more maintenance and rehabilitation.

- Steel corrosion has a devastating impact on critical infrastructure and continuously increases maintenance costs.

- The need for sustainable construction solutions opens new horizons for the composite rebar production sector.

Many leading research institutions have been studying the composite material properties. In many applications, GFRP rebar outperforms traditional steel bars. As a result, leading construction companies shift their focus to composite reinforcement.

According to Market Research Future, the FRP rebar market is estimated at USD 4.16 billion in 2024. Analysts expect that the market size will reach USD 4.74 billion in 2025, with the potential to reach USD 15.38 billion by 2034. If predictions are correct, CAGR is around 14% for the forecast period.

How GFRP Rebar Is Changing the Construction Sector

As the world turns to environmentally responsible construction, GFRP rebar comes to the scene as an alternative to conventional reinforcement materials. Properties like corrosion resistance, durability, strength, and lightweight have made composite materials a preferable option for many residential and industrial projects.

GFRP Rebar: Properties

- Lightweight: ¼ of traditional steel rebar. Result – easier handling and lower transportation costs.

- Durability: Resistant to corrosion and chemical degradation.

- Service life: 100+ years. Result – improved structure lifespan and reduced maintenance costs

- Non-conductive & non-magnetic properties: Suitable for specialized projects, such as medical and aeronautical facilities

The GFRP rebar manufacturing process has a significantly lower carbon footprint compared to steel manufacturing. Longer service life of composites and their resistance to corrosion make them the number one choice for infrastructure projects in harsh environments, such as marine structures, bridges, transportation network elements, and coastal protection. Composite reinforcement also helps to resolve corrosion-related challenges in the construction of building foundations, parking structures, specialized facilities, and exposed architectural elements.

Additionally, the non-magnetic properties of GFRP make it an ideal solution for the construction of healthcare and research facilities where a neutral environment for sensitive equipment is crucial.

This explains why the GFRP rebar manufacturing industry has been growing exponentially during the last decades.

Starting a Fiberglass Rebar Manufacturing Business

GFRP rebar manufacturing business is a very promising sector for investors. The growing demand for durable, strong, and sustainable construction materials drives market expansion. Relatively low initial investments and return on investment within a relatively short term make composite rebar production an attractive business option.

The sector is scalable to various investment levels:

- Entry-level operation. Accessible initial investments and partnership with reputable GFRP rebar machine suppliers ensure a manageable production footprint via the targeted market approach.

- Commercial-scale operation. Increased fiberglass rebar production performance and broader market penetration. The shortened payback period and high return profile open up opportunities to scale up operations.

- Industry-leading position. A full product range and extensive market coverage create new vertical integration opportunities and ensure market leadership advantages.

Factors to Consider Before Entering the Market

To become a GFRP rebar manufacturer and launch a profitable business, you need to develop a comprehensive strategy and consider multiple factors.

First of all, you need to identify the target market and determine the high-value applications. Initially, it is always better to focus on leveraging GFRP advantages in the chosen market. Another crucial aspect is to build lasting partnerships not only with contractors, but also with equipment and raw material suppliers.

Next, you plan an efficient production environment. Operational efficiency relies heavily on facility location for strategic market access. The entry-level business plan should include accommodation for future growth and expansion.

Then, you make the choice of the production systems and technology. Modern production equipment can be configured to meet your specific needs; machines are equipped with built-in quality control systems to ensure consistent product excellence.

Once your business is fully operational, you can expand the product range and manufacturing capacity, step-by-step, strengthening your market position.

Partnership with Composite-Tech: The Road to Success

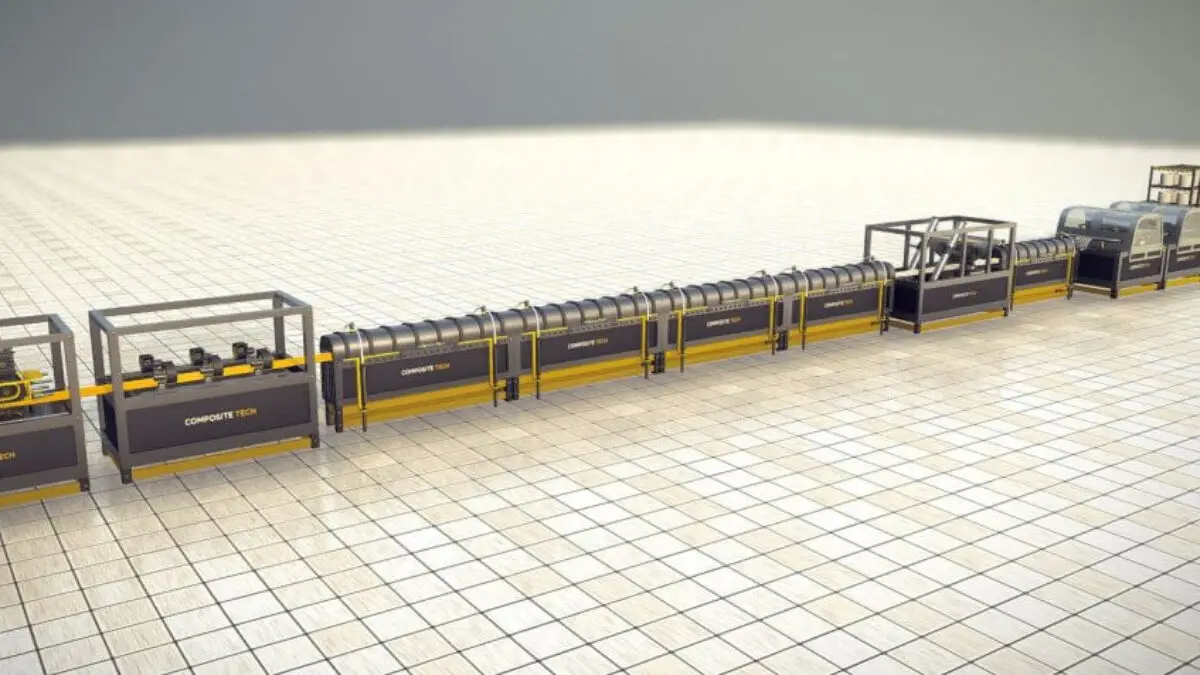

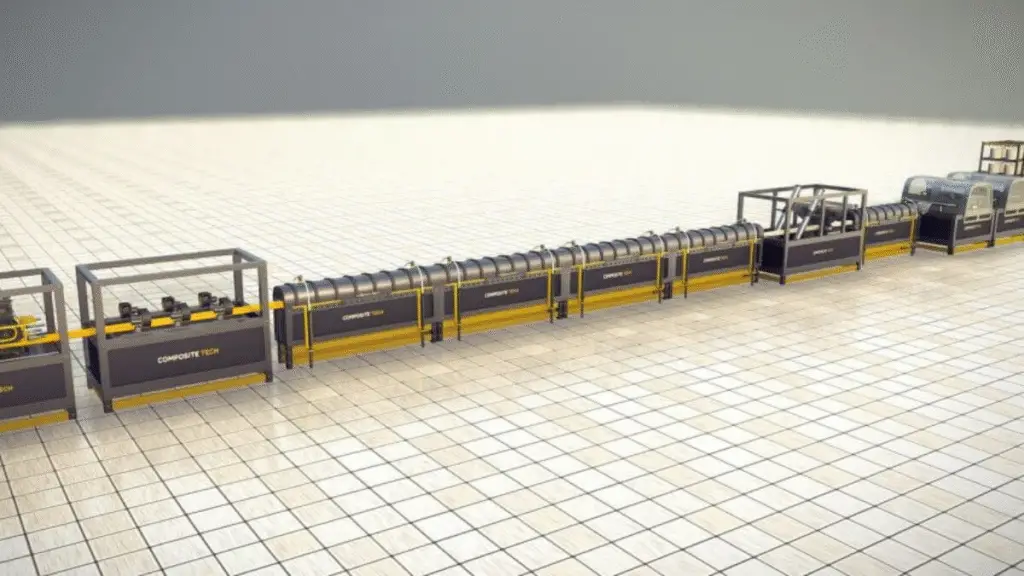

Composite-Tech, a leading FRP rebar production lines supplier, delivers turnkey solutions for companies entering the GFRP rebar business sector. Being a reputable supplier of fiberglass rebar production lines, the company also offers equipment for manufacturing FRP mesh, GFRP bent elements, tanks and silos.

Composite-Tech: We Provide Complete Manufacturing Solutions

Composite-Tech stands out in the market because the company doesn’t just sell equipment, but delivers integrated manufacturing solutions. Tailored modular configuration, automated operations, energy efficiency, waste reduction, and built-in quality control — production machines are designed for optimal flow and maximum efficiency.

Besides technical excellence based on continuous technological improvement based on the most recent research, Composite-Tech’s technical team provides ongoing support for process optimization for specialized product requirements, let alone comprehensive training to ensure operational excellence. The pros will consult you on the requirements to a manufacturing facility and take on the responsibility to install and tune up the equipment.

The company’s specialists work closely with clients to ensure smooth operation and flawless performance of production lines. The team helps partners to avoid costly mistakes and provides comprehensive support in terms of market insights, technological innovations, and much more.

For more information on launching a GFRP rebar manufacturing business, contact Composite-Tech’s team. They will consult you on customized production systems and guide you through the entire process, from initial market analysis to full-scale production.