A strap footing also known as cantilever footing, is a special case of combined foundation in which two separate footings are tied together by a beam called tie beam or strap beam.

Mostly in cities, the houses are adjacent to each other due to limited and congested space available i.e. the outer walls are touching each other and having a limited space for an isolated column footing.

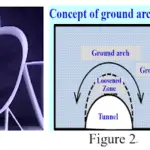

This restriction can also arise in cases when a utility line or some sewerage line is passing the area under construction and the relocation of such service is impossible. The situation is explained in the figure below;-

The column located at the property line has an eccentrically loaded footing. The offset in column’s footing is because otherwise it would encroach into the adjacent property.

So in such cases the cantilever foundation is very handy and useful to ensure structural stability without disturbing the aesthetic appearance of the building. The purpose of providing the strap beam or tie beam is to counterbalance the asymmetrical load.

It is also sometimes termed as balanced foundation. This “specifically” means that the loading from the superstructure is cantilevered out by a ground beam over the pad foundation that is designed to have uniform bearing stress.

What if Strap Beam is not provided?

Well usually in simple isolated footing, the center of gravity for the superimposed loads and that of the footing overlaps and is in one line. But in case of Cantilever footing one column is supporting the superimposed load by cantilever action thus it is not possible and thus strap beam is provided.

The strap beam avoids the overturning effect and thus if the strap beam is not provided the foundation and in turn the structure will overturn.

Due to the eccentricity in column there are huge moments created at the base of the column which causes overturning effects. Hence to overcome these overturning moments a restoring moment/stabilizing moment is required to be produced, mostly by the self-weight of footing and overburden soil over the footing.

Since the cantilever foundation is connected with a strap beam with another footing the moments are resisted by a combined effect of the self-weight of columns, footing and overburden soil pressure from both footings.

If at all you are said to not use strap beam, the plan dimensions and thickness of the footing has to be huge, which economically is bad.

So in a nutshell, technically it is possible to make an eccentric footing without strap beam but economically it is not viable and thus in all such cases a strap beam is seen.

Cantilever Action

Did you know what Cantilever Action is?

Mostly in structure, the elements of buildings are supported at both ends for supporting the applied load.

However, in some cases an overhanging structure is needed like a sunshade or a plinth protection slab away from the structure. In such cases a cantilever structural element i.e. beam or a plate is constructed that is anchored only at one end.

In cantilever structures the applied load is transferred to the single ended bracing by converting it into bending moment and shear stress. The design of element is thus based to resist bending moment and shear stresses.

When to use Strap Footing or Cantilever Footing?

The first situation is already explained above i.e. when the property line restricts the column to be eccentric on a footing. But from design point of view, the cantilever or strap footing is used when

1. X < L/3

2. When the distance between two columns is so large that a combine footing becomes excessively long and narrow.

Design of Strap Footings

The assumption that are made for the design are :-

- Strap is infinitely rigid

- Strap is pure flexural member and does not take soil reaction. (To confirm with this, strap is constructed slightly above soil or soil under strap is loosened.).

- Assume a1, width of the effected footing and establish the eccentricity, e of the soil reaction force R1

e = (a1-a’)/2

e = Xc – Xr - Determine the magnitude of the Soil Reaction force by taking moments about R2

R1 = P1 (Xc / Xr) + Ws (Xs / Xr)

In this equation the weight of the strap, Ws may be neglected if the strap is relatively short. - Determine the reaction R2 from equilibrium consideration

R2 = P1 + P2 + Ws – R1 - Determine the size of footings using known values of R1, R2 and σult.

b 1 = R1 / (σ1 * a1)

b 2 =R2 / (σ2 * a2) - For square footing b2 = a2 = square root (R2 / σa2)

For rectangular footing assume some value of a2 and determine b2.

It should be noted that the actual bearing pressures under the footings should not very different from each other in order to minimize differential settlement. - Determine and draw shear force and bending moment diagrams along the length of the footings.

- Select depths of footings for shear reinforcement.

- Select steel reinforcement for bending requirement.

- In short direction, the footings analyzed as spread footing subject to uniform soil pressure.

- Design strap as flexural member for the shear and moment obtained above.